To preserve a wine's taste and intensity of flavor while maintaining its uniqueness is a delicate balance. Contaminants like crystals, treatment residues, organic aggregates, bacteria and yeast can significantly impact a wine's quality. Applying Pall's technologies and expertise in filtering wine to your process will remove risks and ensure peace of mind by enabling more rigorous process control.

Pall Corporation has a very strong presence in the world of winemaking.

We have installed wine filtering systems in every region of the world at many of the largest wineries, but also at the smallest boutique producers as well as every customer in between. We have been at the forefront of new developments in wine processing for well over a century and our brands are often seen as benchmarks for wine and lees filtration.

- Seitz® filter sheets were first sold to wineries over 130 years ago. Since then, it is estimated that more than a trillion liters of wine have been filtered using our flat filter sheet media.

- More recently our OenoflowTM wine filtration systems changed the way wine is clarified. With over 1,500 installations, the Oenoflow system continues to be the leader globally for crossflow filtration.

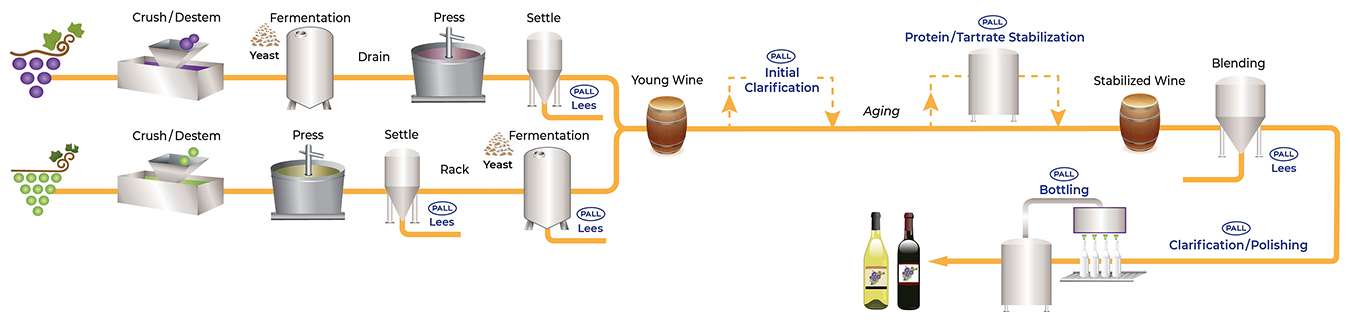

Process Flow Diagram of Wine Making and Pall’s Solutions for Wine Filtration in Every Step

Our solutions and expertise in the wine-making process are demonstrated below with traditional and modern wine filtering system solutions that preserve quality and maintain the lowest operating costs.

Steps in Filtering Wine

-

Wine Clarification

-

Lees Filtration

-

Colloid Removal

-

Protein Stabilization

-

Wine Bottling

-

Activated Carbon

Why is Clarifying Wine Important?

Clarification is the primary filtration step in the winemaking process. Yeasts and other particles from fermentation and fining are removed to reduce turbidity and improve downstream filterability.

The Oenoflow PRO XL System was built to help wineries achieve clarification and protein stabilization. Other benefits include:

- Reduced energy usage to support goals for net zero carbon emissions

- Reduced water usage given considerable water shortages experienced in many regions

Recover Higher Value Wine From Lees

Lees, the sediment at the bottom of juice, fermentation or fining vessels, can represent up to 10% of a winery’s total volume. Recovery of wine and juice from lees represents one of the most challenging forms of filtration faced by wineries.

Recovery of wine and juice from lees represents one of the most challenging forms of filtration faced by wineries. The Oenoflow HS system is a new crossflow filtration system designed specifically for lees processing.

After primary clarification, stabilization and maturation, fining agents, crystals, colloids and bacteria may still be present in the wine. Polishing filtration is designed to remove these particles and haze to produce a brighter wine and improve filterability for downstream processing.

Depth Filtration Technologies

Depth filtration represents a wide range of different filter sheet media which can be used for:

- Turbidity removal, from coarse to fine particles

- Polishing filtration

- Colloidal removal

- Chill haze removal

- Removal of microbial spoilage/ Reduction of microorganism (yeast, bacteria, mold)

Protein stabilization and clarification are two critical steps to satisfying consumer expectations for a bright wine. While both steps prevent haze formation, one to remove heat sensitive proteins, the other suspended solids, the traditional commercial processes are typically carried out in consecutive phases adding labor, time and waste to the winemaking process. With Pall's new Oenoflow PRO XL System with Oenofine Functionality Installed, wineries can now combine these operations into a single cost saving process step.

Removing Contaminants when bottling wine is key to ensuring consistent product quality

As cartridge filtration is the last process step prior to bottling, it is critical to ensure removal of particulates and microorganisms that can result in re-fermentation, turbidity and off-flavors post bottling.

Implementing a well thought out wine bottling program that includes pre filtration and final filtration will ensure that your brand is protected and that your product quality is consistent.

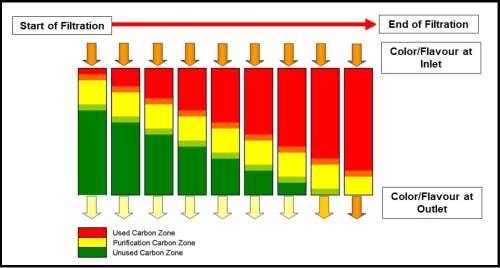

Crafting a wine's inimitable bouquet while maintaining optimal intensity of flavor along with a beautiful color is the goal of every winemaker. However, in some cases, wine may have an off-taste flavor or color as contaminants can jeopardize the winemaker’s efforts. Activated carbon filtration using carbon-impregnated sheets or sheet-based modules, or carbon beds, fixes color and flavor issues. Pall offers adsorptive filtration technology which achieves color, flavor and/or odor correction. These filters have an extremely high adsorptive capacity in the filter sheet matrix and for small batches and batch corrections, carbon impregnated sheets and modules offer a simple and easy way to treat wine. Learn more about Seitz® AKS FB which is I.O.V (International Organization of Vine and Wine) compliant activated carbon media.

Ready to learn more? We can help find the right wine filtration solution for your needs. Contact us.

Wine Filtration Products

For more information about our range of products, explore our product catalog.