Filtration Solutions for Craft Beer & Microbreweries

Craft beer has experienced a steady increase in popularity in recent years. With consumers demanding high-quality, innovative beverages, craft beer breweries can deliver unique beers rich in flavor and taste. Combining the finest raw materials with unique yeast strains and traditional brewing processes, the micro and craft brewers create a fantastic diversity of beers based on historic and new recipes. Commercial Craft and micro brewers are known to focus on full flavor, greater variety and above all, quality.

How can craft breweries ensure the quality of their filtered beer?

Beer quality is a top priority for producers and consumers. The craft brewing process must meet high standards for preserving a brew's unmistakable taste, flavor, purity and freshness. Creating that unique taste and maintaining uniformity of flavor from bottle to bottle, brewery to brewery and brand to brand requires delicate precision.

Filtration plays an important role in ensuring the success of micro and craft beer breweries. Applying the right type of clarification is as important as the cold microbial control of the product and used media. Pall provides specially developed beer solutions, which add value to the craft and micro brewing process to maintain freshness and stability over time.

Covering clarification, microbial control, utility service filtration, integrity testing and final filtration, Pall offers complete brewery solutions. Select the links below to find out more about each unit operation or process step.

-

Clarification

-

Final Filtration

-

Service Filtration

-

Integrity testing

Beer filtration and clarification are an essential step in beer production. Clarifying beer involves removing solids and yeast after fermentation and maturation, and methods to achieve clarification sustainably have improved greatly.

Essential to the craft brewing process is the final filtration stage. The brewing process is sensitive to beer spoiling microorganisms which can ruin the taste and occurrence for your consumers. Final craft beer filtration plays an important role in product quality and can prevent any harmful contaminants from making it through to the final product.

-

PAL932_fb1793

Download:

Service Filtration gas and water supply

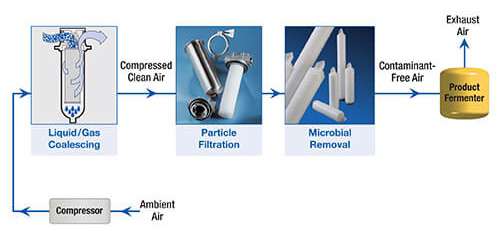

Utility fluids such as water, air, steam and other gases support the manufacturing processes and represent the basic building blocks to create products or enable plant operations. Securing the quality of utilities based on their end-use requirements is a good manufacturing approach that proactively eliminates problems, safeguards the process, and allows brewers to focus on the larger challenges they face. Pall can help our customers with these basic.

-

Mechanisms of Air and Gas Filtration

Download:

Integrity testing helps to ensure quality. Performed before or after filtration without affecting the filter itself, the integrity tests provide the confidence that the final membrane filters are operating as expected.

Pall’s food and beverage portfolio is comprised of many integrity test devices that help the industry ensure membrane filters are integral and suitable for continued service.

Looking for something else? Discover other beer filtration solutions here:

BEER - CRAFT & MICRO BREWERIES Products

For more information about our range of products, explore our product catalog.