Critical biofuel filtration technology for sustainable transportation fuels

With global greenhouse gas (GHG) emissions from transport growing faster than any other sector, the use of advanced biofuels is one promising alternative to reducing our dependence on petroleum-based fuels and reducing climate change. The production of advanced biofuels is not without its challenges. Variation in the feedstock sources as well as feedstock degradation results in contamination issues from the type and size of impurities. To protect downstream equipment, preserve catalyst life, and to ensure the final product meets specifications, filtration technology selection is a critical component.

Another critical challenge in our modern world is in dealing with increasing amounts of organic waste produced through animal, industrial and food sources. Processing organic waste to create biogas offers an alternative to natural gas for use in transportation fuels, heating, and power generation. This helps reduce waste at landfill and mitigate the methane emissions that would have otherwise escaped, diminishing its climate impact.

As a global leader in filtration technology and solutions, we understand that one solution cannot fit all. Our experts will provide bespoke solutions tailored to your needs in partnership with you. To find out more, contact us.

Watch our On-demand Webinar: Keeping it Clean and Green!

Learn from Pall experts on the filtration challenges in renewable fuel processes.

To learn more about how our filtration solutions can support advanced biofuels production, contact our filtration experts.

Customer Success Stories

Removing contamination from used cooking oil feedstock at a European refinery

Challenge

Presence of gels and particles in diesel hydrotreater feed due to blending of used cooking oil feedstock

Solution

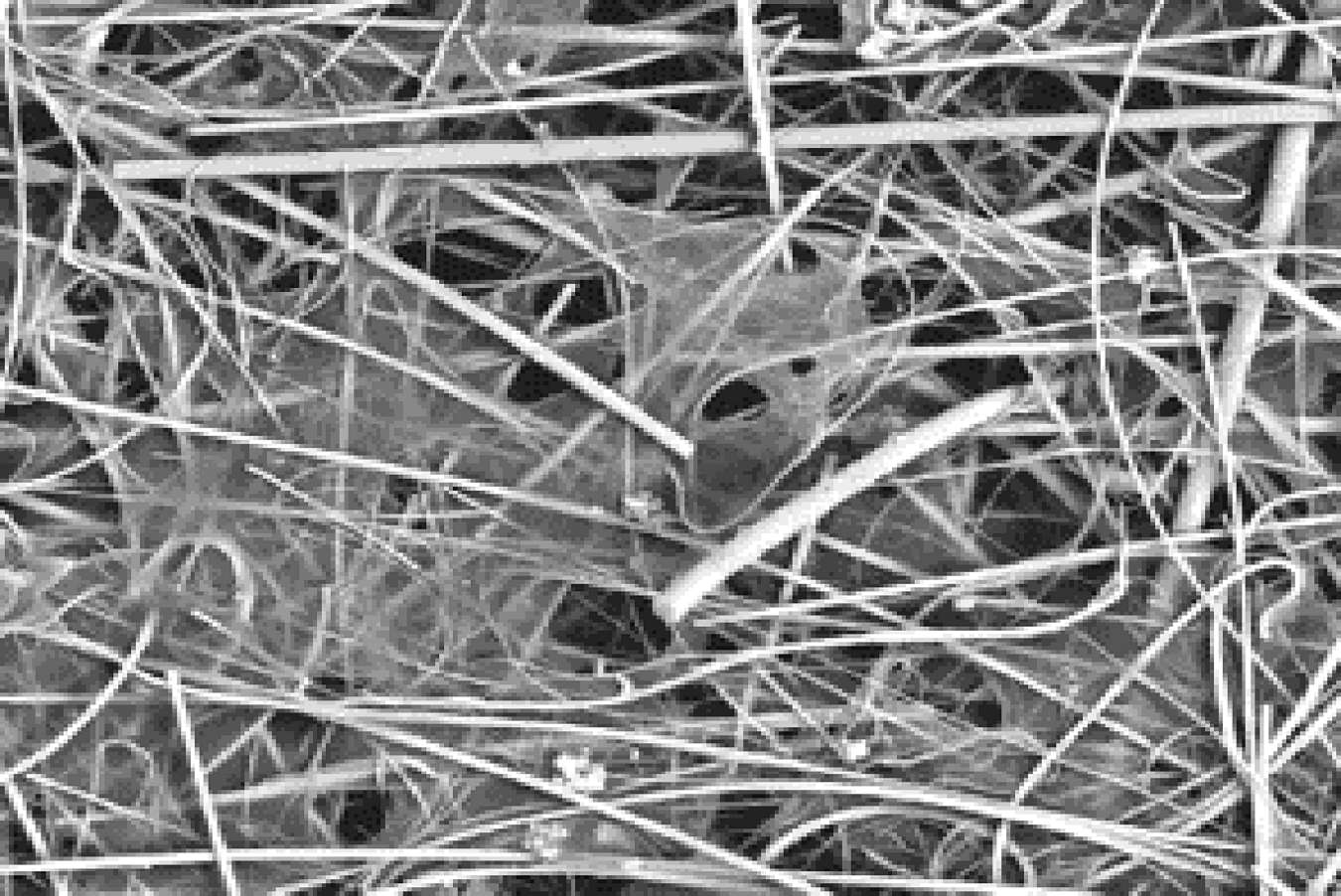

Pall's filter cartridges with Laid-Over-Pleat technology helped achieve high solids and semi-solids removal

Impact

- Integration of new bio-feed

- Extended catalyst life

- Reduced heat exchangers maintenance

Developing a filtration strategy to handle renewable Tall Oil Feed

Challenge

Refinery was unable to operate existing feed filters due to poor performance and short life from excess contamination in Tall oil Feed

Solution

Pall analyzed feed samples in the lab to determine the best approach and supplied rental skids to demonstrate performance in the field

Impact

- Zero CAPEX solution due to rentals

- Optimal filter design using contamination mapping

- Process troubleshooting with Pall Experts

Bio-refinery meets stringent specifications for premium diesel thanks to Pall Solution

Challenge

Customer was unable to meet total suspended solids and water content specifications

Solution

Pall supplied mobile pre-filters and liquid-liquid coalescers, which achived consistent filtration and seperation to meet premium diesel specifications

Impact

- Results achieved with zero CAPEX due to ue of mobile skids

- OPEX optmization ongoing wuth support from Pall experts

Helping achieve reliable operation for US refiner of beer tallow

Challenge

Customer needed improved filter life and performance

Solution

After extensive lab testing and field verification, Pall offered the optimal solution that increased filter life and improved downstream asset protection.

Impact

- Superior dirt holding capacity, increased filter life, and lower price than competitors

- Reduced CAPEX using Pall solutions