Junte-se à Brew Crew e assine hoje mesmo! Mantenha-se atualizado sobre filtração de cerveja, eventos e promoções aqui:

Soluções de filtração para cerveja artesanal e microcervejarias

As cervejas artesanais têm experimentado um aumento firme na popularidade nos últimos anos. Os consumidores desejam bebidas inovadoras e de alta qualidade, e cervejarias artesanais podem oferecer produtos ricos em textura e sabor. Combinando as matérias-primas mais finas com cepas de leveduras únicas e processos de fermentação tradicionais, microcervejarias e cervejarias artesanais criam uma diversidade fantástica de cervejas com base em receitas novas e históricas. Microcervejarias e cervejarias artesanais comerciais são conhecidas por se concentrar no sabor pleno, maior variedade e, acima de tudo, qualidade.

Como as cervejarias artesanais podem garantir a qualidade de suas cervejas filtradas?

Melhor qualidade é uma prioridade para produtores e consumidores. O processo de fermentação artesanal precisa atender padrões altos para preservar o gosto inconfundível, sabor, pureza e frescor. Criar esse sabor único e manter a uniformidade do sabor de uma garrafa para outro, de cervejaria para cervejaria e marca para marca exige precisão delicada.

A filtração desempenha um papel importante para o sucesso de microcervejarias e cervejarias artesanais. Aplicar o tipo de clarificação correto é tão importante quando o controle microbiano a frio do produto e o material filtrante usado. A Pall possui soluções desenvolvidas especialmente para cervejarias que agregam valor ao processo de fermentação para manter o frescor e a estabilidade ao longo do tempo.

A Pall oferece soluções completas para cervejarias que abrangem clarificação, controle microbiano, filtração de serviços públicos, testes de integridade e filtração final. Selecione os links abaixo para saber mais sobre a operação de cada unidade ou etapa do processo.

-

Clarificação

-

Filtração final

-

Filtração de serviços públicos

-

Teste de integridade

A filtração e a clarificação da cerveja são etapas essenciais na fabricação dessa bebida. A clarificação da cerveja envolve a remoção de sólidos e leveduras após a fermentação e a maturação, e os métodos para obter clarificação sustentável melhoraram muito.

Essencial ao processo de fermentação é o estágio de filtração final. O processo de fermentação é sensível a micro-organismos de deterioração de cerveja que pode arruinar o gosto e a ocorrência para os seus consumidores. A filtração final da cerveja artesanal desempenha um papel importante na qualidade do produto e pode evitar que contaminantes prejudiciais cheguem ao produto final.

-

PAL932_fb1793

Baixar:

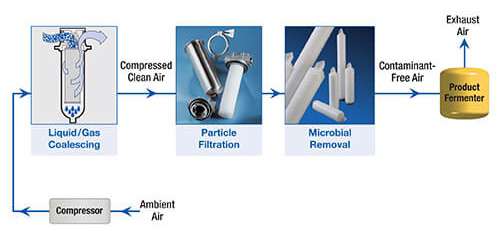

Filtração do fornecimento de gás e água

Os fluidos de utilitários como água, ar, vapor e outros gases que suportam o processo de fabricação e representam os blocos de construção básicos para criar produtos ou que permitem as operações da planta. Assegurar a qualidade desses fluidos utilitários em suas exigências de uso final é uma boa estratégia de manufatura que elimina problemas de forma proativa, salvaguarda o processo e permite aos fabricantes de alimentos ter como foco os desafios maiores que eles enfrentam. A Pall Corporation pode ajudar os clientes a dar conta dessas estruturas básicas. A Pall pode ajudar nossos clientes com esses suprimentos básicos.

O teste de integridade ajuda a garantir a qualidade. Executado antes ou depois da filtração sem afetar o filtro em si, o teste de integridade proporciona a certeza de que os filtros de membrana finais estão operando conforme o esperado.

O portfólio de alimentos e bebidas da Pall é composto por vários dispositivos de teste de integridade que ajudam a indústria a garantir que os filtros de membrana sejam integrais e adequados para serviço contínuo.

Está buscando outra coisa? Descubra outras soluções de filtração de cerveja aqui:

CERVEJA - Produtos PARA CERVEJARIAS ARTESANAIS E MICROCERVEJARIAS

Para mais informações sobre a nossa linha de produtos, consulte o nosso catálogo.