Reduza seu impacto ambiental aproveitando a tecnologia mais recente da Pall.

Desde 1946, a Pall vem ultrapassando os limites da ciência e da tecnologia para solucionar os desafios mais complexos de filtração, separação e purificação. O sistema Oenoflow PRO XL foi construído para ajudar as vinícolas a alcançar dois objetivos importantes:

- Reduzir o uso de energia para apoiar as metas de emissões líquidas de carbono zero

- Reduzir o uso de água devido à considerável escassez experimentada em muitas regiões

Os dados mostram reduções de até 60% no uso de energia e água com o Oenoflow PRO XL em comparação com os sistemas Oenoflow tradicionais.

Os sistemas Oenoflow PRO XL são especificamente projetados para atender às necessidades e exigências de vinícolas de médio e grande porte. A clarificação é obtida em uma única etapa do processo, sem a necessidade de auxiliares de filtração, centrifugação ou impacto significativo nas características organolépticas do vinho. Ao aumentar os rendimentos, reduzir os volumes de resíduos e manter a qualidade do filtrado mais consistente, os sistemas totalmente automatizados fornecem uma alternativa sustentável com economia de custos aos métodos tradicionais de clarificação de vinho.

Os sistemas utilizam membranas de fibra oca da Pall com resistência mecânica única e excelente resistência química que permitem alta produtividade e exposição repetida a regimes de limpeza agressivos. Os módulos da área de superfície grande permitem a fabricação de sistemas compactos com consumo baixo de água e de produtos químicos de acordo com os programas de conservação da vinícola.

O sistema Oenoflow PRO XL introduz o novo algoritmo otimizador da Pall que ajusta automaticamente as configurações do sistema em tempo real, com base nas características químicas e individuais do vinho.

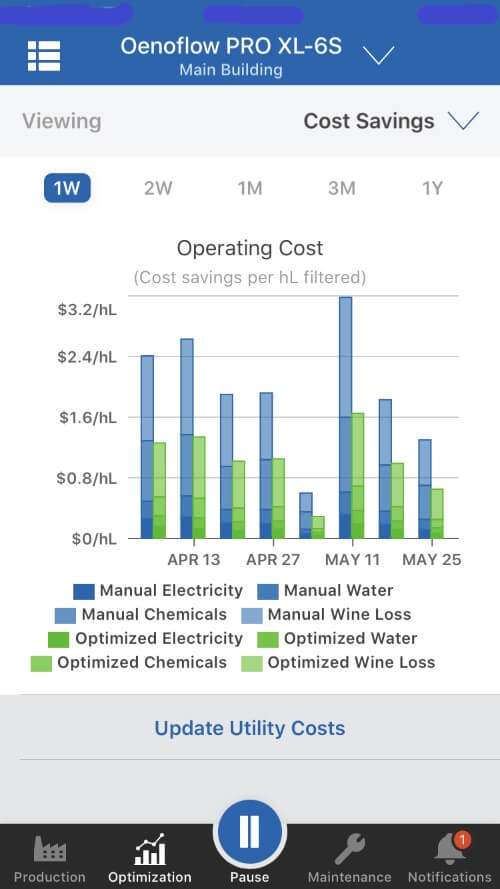

Com este desempenho muito melhorado, vinícolas com o novo sistema Oenoflow PRO XL pode obter economias em todas as categorias de despesas operacionais em comparação aos sistemas Oenoflow tradicionais.

Essas configurações otimizadas substituem as configurações padrão que não são eficientes para todos os ciclos de produção. O algoritmo otimizador Oenoflow PRO aprende e ajusta as configurações para ajudar vinícolas a obter os melhores resultados para cada filtração.

Com a automação avançada do sistema Oenoflow PRO e a facilidade de uso, os clientes podem esperar menos erros de operação e eliminar a variação de desempenho entre operadores.

O Oenoflow PRO com o Optimizer permite inclusive que operadores gerenciem o sistema com total eficiência em seu primeiro dia ao tirar proveito da experiência global em filtração da Pall, combinada com a facilidade de uso do novo software do sistema Oenoflow PRO .

O sistema Oenoflow PRO é composto por 4 componentes principais:

O sistema Oenoflow PRO opera com o novo algoritmo otimizador da Pall e é conectado aos servidores da Pall por meio de uma conexão segura.

- O algoritmo Optimizer recebe atualizações por meio de conexão remota, mas o sistema continuará a operar se a conexão for interrompida.

- O algoritmo Optimizer ajusta todas as configurações do sistema de filtração; o usuário precisa somente inserir informações limitadas do lote no início da filtração.

- O algoritmo pode facilmente ser ativado ou desativado pelo usuário a qualquer momento.

Os aplicativos Oenoflow PRO para IOS e Android já estão disponíveis e se conectarão ao(s) sistema(s) Oenoflow PRO do cliente.

- Diversos níveis de usuário designados pelo “Supervisor” da vinícola para controle específico de acesso do site

- Notificações "push" para alarmes e atualizações de status.

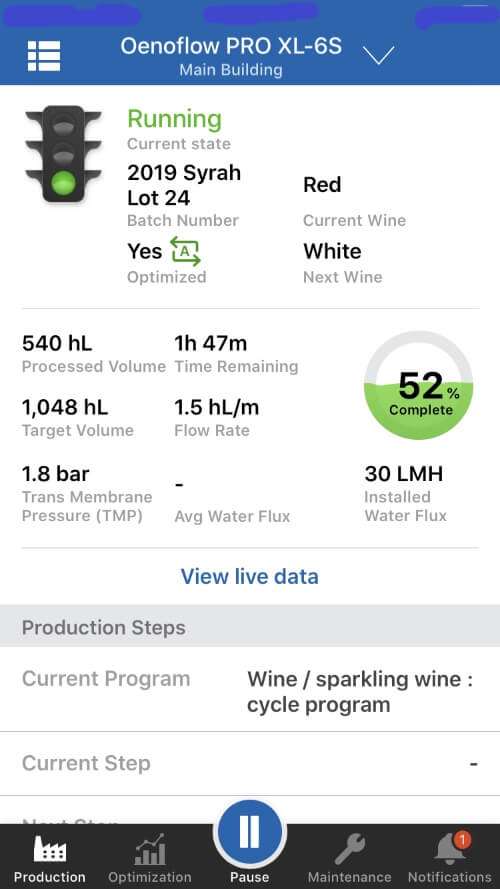

- Visualização em tempo real dos dados de produção e diagnóstico remoto.

- Resumos dos custos operacionais por máquina e por site, classificados por tipo de despesa.

- Função de “Pausa remota do sistema” disponível se ativada pelo cliente, sem possibilidade de reinicialização remota.

- Armazenamento de manuais do cliente, listas de peças de reposição e contatos de serviço.

- Entrada do histórico de eventos de serviço.

Painel baseado no navegador para acesso ao desktop

- Diversos níveis de usuário são designáveis pelo “Supervisor” do cliente para controle específico de acesso do site.

- Notificações "push" para alarmes e atualizações de status.

- Visualização de dados em tempo real para verificar em tempo real os dados da produção.

- Resumos dos custos operacionais por máquina e por site, classificados por tipo de despesa.

- Histórico do lote para total rastreabilidade.

- Armazenamento de manuais, listas de peças de reposição e contatos de serviço.

- Entrada do histórico de eventos de serviço.

- Armazenamento de documentos do sistema gerenciado pelo cliente para itens como relatórios de auditoria, SOPs do cliente, etc.

Nova IHM (interface homem-máquina) para operação simplificada e consistência com o aplicativo Oenoflow PRO e aparência do painel

Resumo:

- Executivos/gerentes podem acompanhar o uso de água e energia de cada sistema, cada vinícola ou de todo o grupo de vinícolas, conforme necessário. O sistema Oenoflow PRO simplifica as operações ao agregar dados de cada máquina ao painel específico do cliente.

- Os supervisores de produção podem acessar dados no painel e baixar relatórios exibindo o histórico da filtração de cada máquina, incluindo a verificação de limpezas registrada pelo medidor de condutividade incluído.

- Operadores podem usar o novo aplicativo móvel ou para desktop do sistema Oenoflow PRO para visualizar o status da produção, volume restante a ser filtrado e alarmes, em tempo real. Isso permitirá que tenham mais liberdade para executar outras tarefas enquanto operam o sistema Oenoflow PRO . A própria tela IHM no sistema Oenoflow PRO também é atualizada, aumentando ainda mais a facilidade de uso.

- O pessoal da manutenção pode usar o aplicativo móvel ou para desktop do Oenoflow PRO para acessar manuais, listas de peças de reposição, registros de serviço e até mesmo solicitar uma visita de serviço aos técnicos da Pall.

- Os técnicos da Pall podem iniciar o diagnóstico remoto de problemas do sistema assim que eles forem notificados. Isso economiza um tempo significativo e pode, em alguns casos, evitar completamente a necessidade de uma visita ao centro.

1. Para clientes atuais que já possuem um sistema Oenoflow XL-A ou XL-S, basta entrar em contato com um representante da Pall para obter detalhes sobre como atualizar a unidade existente.

2. As reduções no uso de energia e água são baseadas em experiências anteriores e não devem ser usadas para prever o desempenho futuro.

3. Perguntas frequentes sobre dados/conectividade disponíveis.

Preparado para saber mais? Podemos ajudar a encontrar a solução de filtração de vinho certa para suas necessidades. Entre em contato.