Soluções econômicas de tratamento de recuperação de óleo

O setor automotivo, por sua natureza, consome enormes quantidades de lubrificantes, desde óleos de motor e óleos de transmissão derramados em sistemas de transmissão até óleos hidráulicos usados em prensas de estamparia e máquinas de moldagem por injeção. Em quase todos os grupos motopropulsores ou montadoras, dezenas de toneladas de lubrificantes usados são descartados todos os anos, representando um custo operacional recorrente e uma ameaça real ao meio ambiente.

No entanto, a maioria desses lubrificantes usados pode ser recuperada e usada novamente. Desde testadores de função, prensas de estampagem e robôs hidráulicos, o tratamento correto do óleo recuperado é uma fonte de economia imediata de custos, além de ser adequado ao meio ambiente.

Passos para remover a contaminação do óleo

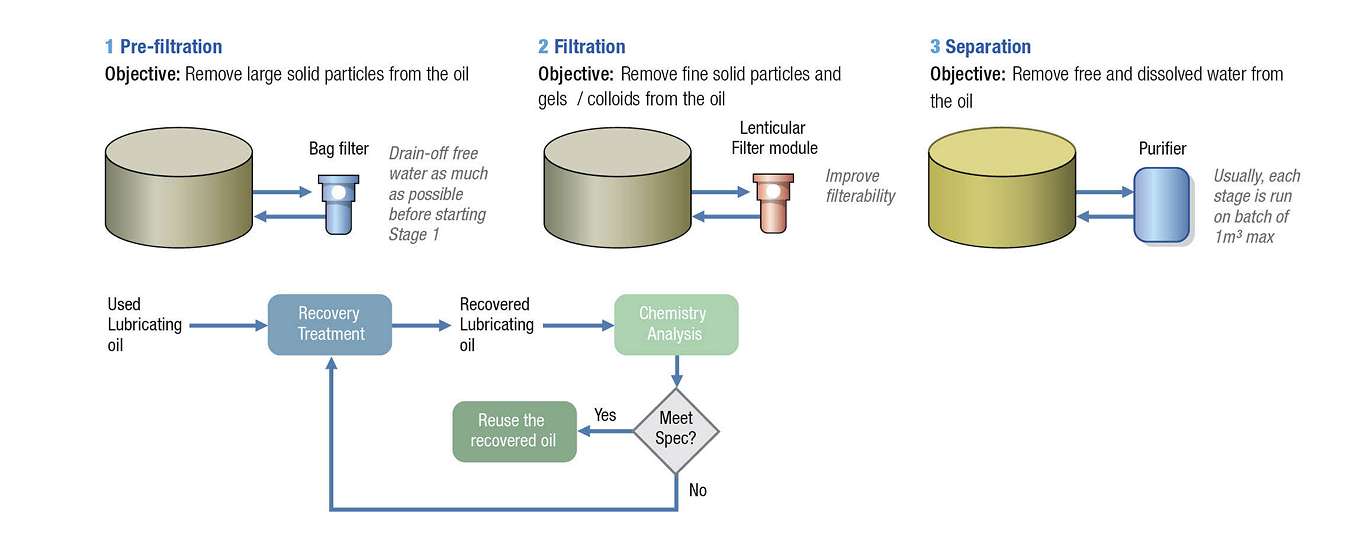

Ao aplicar tecnologias de filtração e separação para remover a contaminação e melhorar a qualidade, óleos usados podem ser recuperados:

Pré-filtração: a remoção de grandes partículas sólidas do óleo pode ser obtida com filtros bag.

Filtração: o uso de SUPRAdisc™ removerá partículas sólidas, géis e colóides do óleo.

Separação: os graus de filtro Athalon™AN ou AS removerão água livre e dissolvida do óleo com eficiência.

A tecnologia de filtração e separação da Pall aplicada no tratamento de reciclagem de óleo industrial permite a montadoras e fornecedores:

- Reduzir o consumo de óleos novos

- Reduzir os custos de operação

- Melhorar a pegada de carbono geral

Para obter mais informações sobre as soluções da Pall para tratamento de recuperação de óleo, entre em contato com nossos especialistas no formulário fornecido.

Para saber mais sobre como melhorar a eficiência de seus processos, contate nossa equipe de especialistas em filtração.

Nossos produtos

Liderando o setor com soluções de produtos que atendem às necessidades dos seus clientes.

Lavagem de Peças

Limpeza da Linha Fluida