The Paris Agreement of Dec 2015, the international treaty on climate change signed by 197 countries, recognized the need to contain climate temperature increases to <1.5 C (2.7 F) to avoid a global environmental catastrophe.

To achieve this long-term goal, countries aim to reach global peaking of greenhouse gas emissions as soon as possible and to achieve a climate-neutral world by mid-century. The stark reality is that the world needs to capture 5.6 gigatons of CO2 by the year 2050, compared to the 40 Mtpa captured today.

There are numerous approaches currently employed to separate CO2 from gas streams, the most common being

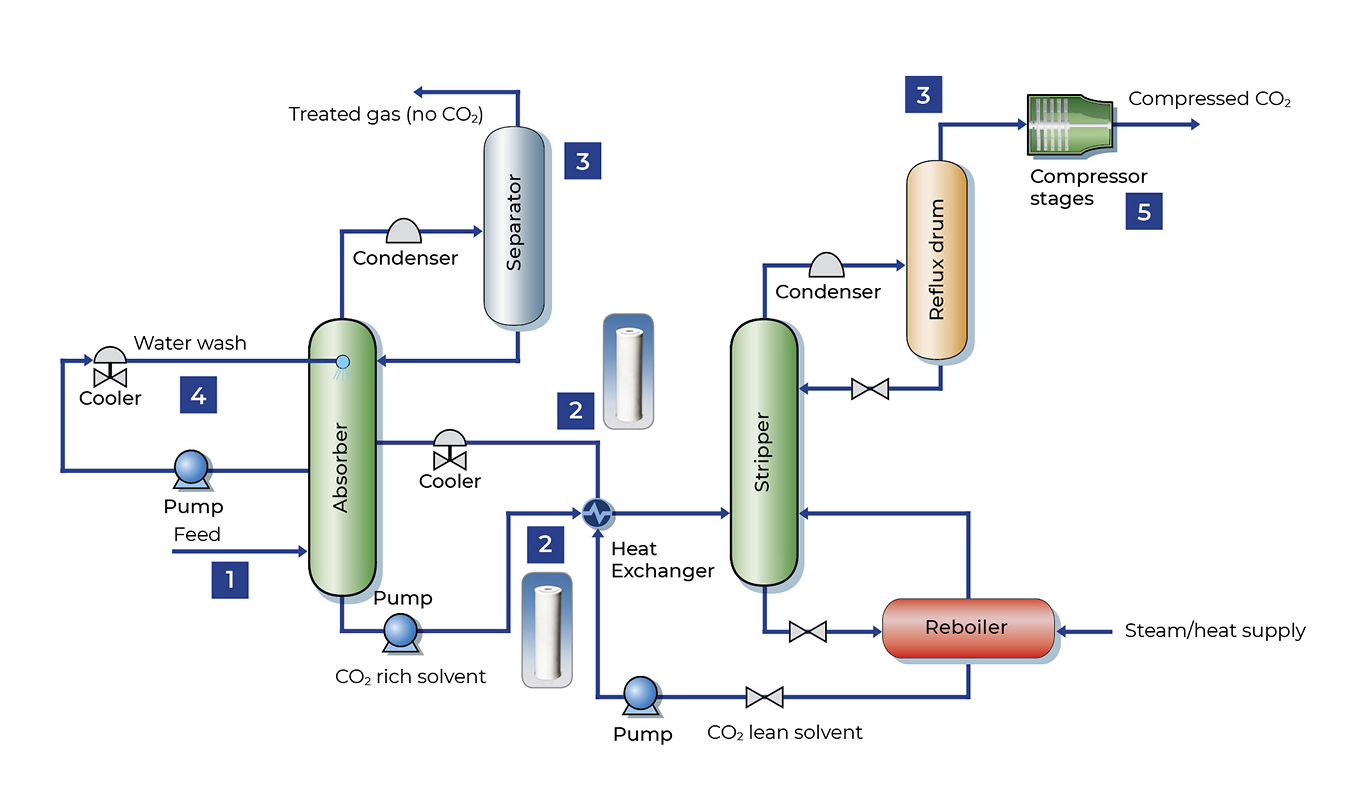

- Absorption - CO2 gas is chemically absorbed in a liquid solvent such as amine

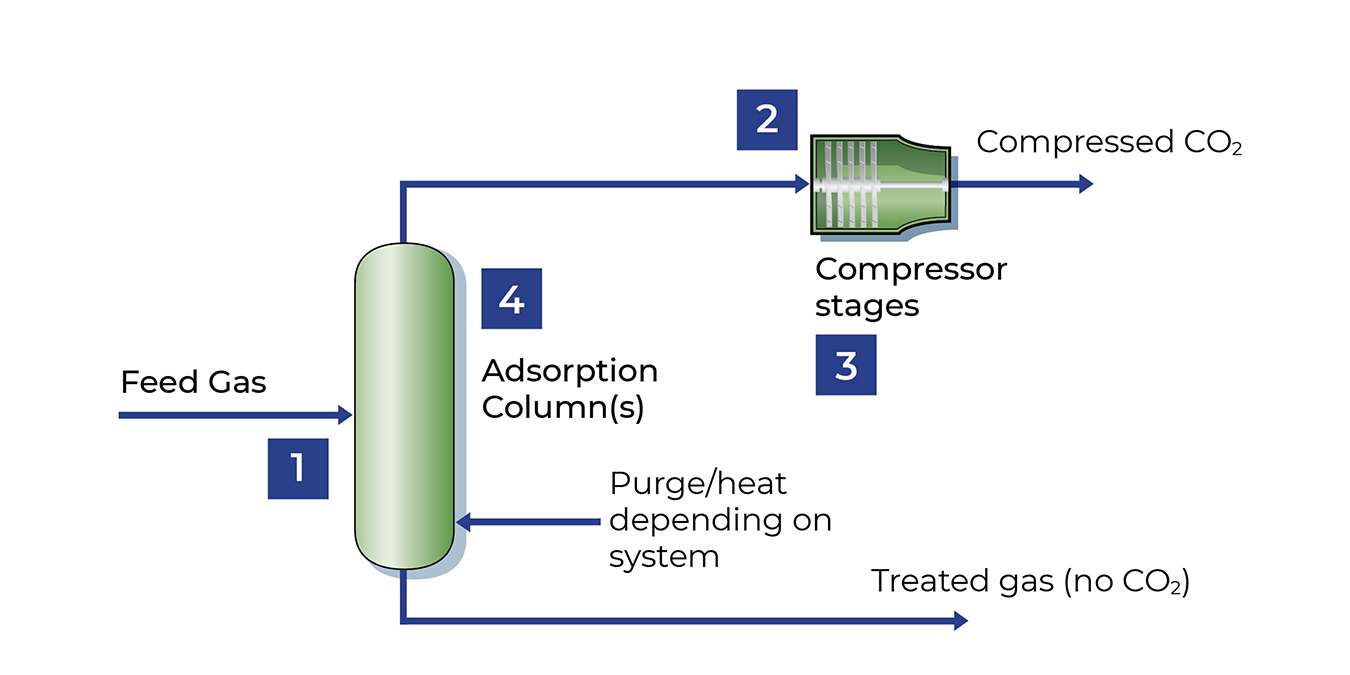

- Adsorption - CO2 gas is captured within a suitable media i.e. an adsorbent bed.

- and in a future state, membrane separation and other methods such as cryogenics or chemical looping

Once the CO2 is captured, it is compressed and either stored or utilized. Common end-uses include urea production and enhanced oil recovery (EOR).

Each capture and utilization approach has unique filtration and separation needs that can be met using Pall technologies. Several separation needs are outlined below.

Absorption - where a solvent such as amine is used to capture CO2

- Feed particulate contaminants and aerosols removal with particulate filters & liquid/gas (L/G) coalescers

- Vent gas cleanup to recover solvent aerosols and meet emissions specs with L/G coalescers,

- Keep capture efficiency high, reduce foaming, and protect heat exchanger equipment by removing degradation products and contaminants in the solvent loop with particulate filters and L/L coalescers

- Maintain fluid cleanliness in dehydration and compression systems with particulate filters

- Downstream equipment and pipeline corrosion protection with particulate filters and L/G coalescers

Adsorption - where an adsorbent such as activated carbon, zeolites or metal oxides are used to capture CO2

- Feed particulate contaminants and aerosols removal with particulate filters & liquid/gas (L/G) coalescers,

- Protect compressors with L/G coalescers to remove water and particulate filters to remove any adsorbent fine carryover or other contaminants,

- Maintain fluid cleanliness in dehydration and compression systems with particulate filters

- Pall is a materials science company and can provide media as a support for adsorbent materials

Speak to one of our regional experts to find out how Pall's wide range of advanced filtration solutions, technical know-how and industry experience can benefit you.

Literature Library

For more information on particulate and coalescer filters applied to CCUS processes, select from the products below

PhaseSep EL Liquid/Liquid Coalescers

Profile Coreless Particulate Filters

For long or short term rental, full and pilot scale equipment, select the PRO SERVICES banner

Download our NEW White Paper

-

Adding value in the journey towards net zero carbon emissions with filtration and separation

Enter your details to download

Pall in the Press

Read our articles featured in leading titles in the industry trade press

Maximizing the Impact of CCUS, Filtration+Separation, May 2023