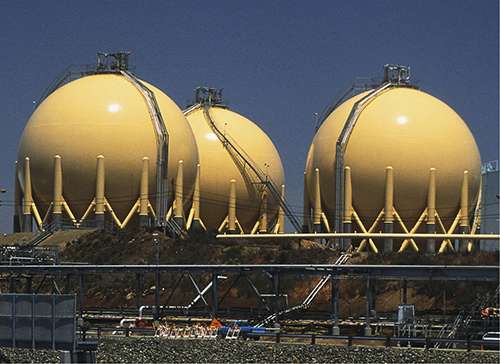

Maximize o desempenho e a confiabilidade de sistemas de refino a jusante de petróleo e gás

Soluções para estender a vida de equipamentos

O refino a jusante de petróleo e gás depende da pureza dos fluxos de alimentação para reações de processo eficientes. A remoção de fluidos e contaminantes particulados das correntes de alimentação e dos processos de recirculação de fluidos é essencial para melhorar a eficiência do refino - Downstream.

Nossas soluções avançadas de filtração de matéria-prima para petróleo e gás oferecem filtração premium e desempenho de separação de fluidos para diversas aplicações de refino, como alquilação, tratamento cáustico, hidroprocessamento de produtos finais, HF, sistemas de recirculação de aminas e catalisadores, separações de fluidos e muito mais. Quer sejam matérias-primas de hidrocarbonetos ou sistemas de fluidos de suporte, como solventes ou catalisadores, os fluxos de fluidos sem contaminantes facilitam reações eficientes e melhoram a qualidade de resultados.

Aplicações de refino a jusante de petróleo e gás

Com materiais e designs de mídia avançados, nossas soluções de filtração maximizam a captura de contaminantes que não são apenas prejudiciais ao processo imediato, mas posteriormente podem danificar equipamentos, resultando em intervenções de manutenção demoradas e caras. Devido ao aumento da capacidade, a frequência das atividades de manutenção do filtro é significativamente reduzida para que sejam diminuídos os custos operacionais. Para fluxos de reciclagem de fluidos, nossa filtração de alto desempenho aumenta a vida útil de fluidos caros, como solventes e catalisadores.

As soluções de filtração avançada oferecem desempenho superior para uma ampla gama de aplicações de refino a jusante de petróleo e gás

Nossos produtos de filtração e separação de refinaria a jusante são projetados especificamente para maximizar a remoção de contaminantes e operar com vida útil mais longa para uma operação verdadeiramente simplificada que afeta direta e positivamente o desempenho dos negócios.

No ambiente de negócios atuais, a eficiência do processo de refinaria é mais importante do que nunca. Minimizar o tempo de inatividade, melhorar as reações do processo, o resultado dos produtos e reduzir os custos operacionais são essenciais para otimizar o desempenho dos negócios. Soluções de filtração eficazes e confiáveis têm impactos diretos e significativos em cada uma dessas questões. Como líder global em tecnologias de filtração inovadoras, entendemos os pontos fracos da operação de refino de óleo a jusante e desenvolvemos uma solução de filtração premium para melhorar o desempenho em vários processos de refino a jusante.

Ao longo da operação de refino - Downstream, as atividades de manutenção programada e não programada são os principais contribuintes para o tempo de inatividade operacional. Independentemente do processo, seja alquilação, tratamento cáustico, filtração de matéria-prima, ou qualquer outra coisa, a contaminação apresenta riscos significativos que podem resultar em tempos de inatividade grandes e caros. Com nossas soluções de filtração, a remoção de contaminantes é maximizada, o que reduz muito o risco de falha do equipamento e intervenções não programadas para manutenção. Além disso, com uma vida útil mais longa, a frequência das operações de manutenção programada é reduzida.

A pureza das matérias-primas e os fluxos de fluidos de suporte, como solventes e catalisadores, são essenciais para a produção de produtos finais de alta qualidade. Nossas tecnologias de filtração e separação eficazes e confiáveis removem contaminantes prejudiciais e facilitam a reação eficiente de refino que melhora a qualidade do produto final e minimiza o desperdício de produto.

Nossas soluções avançadas de filtração de matéria-prima para petróleo e gás são projetadas para melhorar o processo de refino a jusante por meio da remoção eficaz e confiável de contaminantes, redução do tempo de inatividade para manutenção, vida útil prolongada do equipamento e qualidade aprimorada do produto final para uma operação verdadeiramente simplificada e desempenho de negócios significativamente aumentado.

Entre em contato com nossa equipe de especialistas em filtração para saber mais sobre as soluções inovadoras de filtração de alto desempenho da Pall para aplicações em refinarias.

REFINARIA Produtos

Para mais informações sobre a nossa linha de produtos, consulte o nosso catálogo.