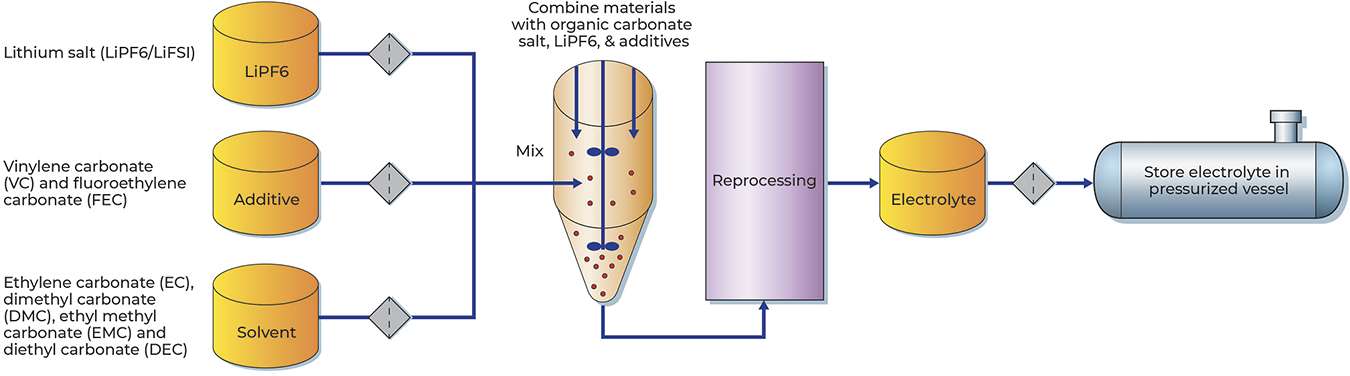

Electrolytes enable the flow of current in the cathode and anode in batteries, facilitating the electrochemical reaction that stores and releases energy. Although there are a variety of electrolytes available in the market today (liquid, solid, etc.), the predominant electrolyte used is Lithium hexafluorophosphate (LiPF6) which is often used with other additives. To maximize the performance of the electrolyte, i.e. high ionic conductivity associated to a high chemical/electrochemical stability, solid particle content must be minimized. To do so, the liquid electrolyte must be filtered before the filling phase.

Pall Corporation: Experts in Electrolyte Filtration

Due to the high degree of acidity of the electrolyte, chemically resistant filter materials and fluoropolymer coated stainless steel filter vessels are recommended. Furthermore, high cleanliness levels are required leading to the use of very fine particulate removal filter ratings (from 0.45µm to 2µm). Depending on the processing lines, different Pall filtration technologies/configurations are used to minimize the total cost of ownership. A process schematic for the electrolyte production process, identifying the purification steps, is shown below.

Learn more about the solution that can support your applications or contact an expert today.