What are SUPRApak Modules?

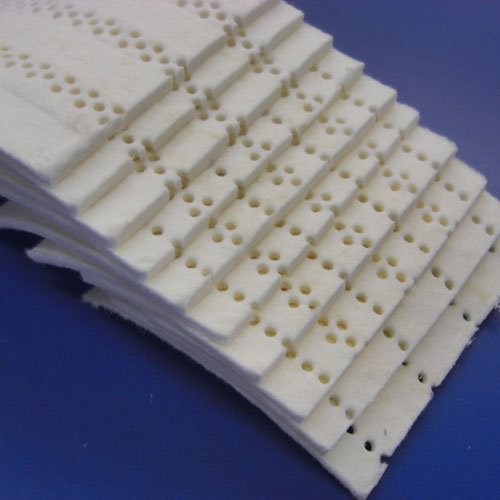

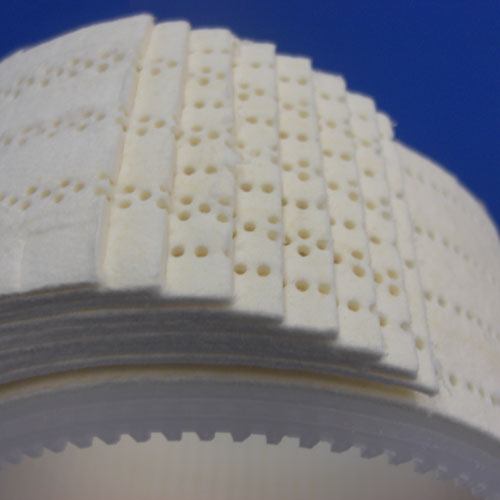

SUPRApak modules are Pall’s latest innovation in depth filtration with an entirely unique design and flow configuration. SUPRApak modules consist of filter sheet material wrapped around a central permeable core with external straps that attach the sheet material to the core. The sheet material is punched with an intricate pattern of feed and filtrate channels which direct fluid flow through the module. The unfiltered fluid enters the module from the outside through feed channels. The differential pressure pushes the fluid flow through the sheet media in a direction toward the filtrate channels. The filtrate channels then carry the fluid toward the center core, where it exits the modules.

Why SUPRApak Modules?

Unique to the SUPRApak module is an entirely new flow control system based on the “Edge flow principle”. This helps to utilize the full capacity of the depth filter media and effectively combines three filtration mechanisms: surface filtration, depth filtration, and adsorption. This design also provides a higher available filter area on 7.5”, 12”, and 16” sizes compared to classical lenticulars.

| FEATURE | BENEFIT | VALUE |

|---|---|---|

| Flow configuration based on “edge flow” principle |

|

|

|

| |

| Enclosed filtration system |

|

|

| Drainable, low hold-up volume assembly |

|

|

High filtration capacity in compact design |

|

|

| Simple, quick installation and servicing |

|

|

-

Classical DE Sheet Media

-

Ion Reduced Sheet Media

-

Pure Cellulose Sheet Media

-

Case Studies and Videos

SUPRApak SW Series Modules

Meet the entire range of removal requirements in the food and beverage industry. Available in multiple grades suitable for microbial reduction and applications requiring fine, clarifying and coarse filtration.

SUPRApak SR Series Modules

Besides cellulose, kieselguhr and perlite, filter sheet material of the SUPRApak SR-series contains up to 40% of polyolefin fibers, specially selected for best possible filtration results. These filter sheets are characterised by an increased chemical and mechanical stability. They are therefore particularly suitable for the filtration of aggressive media. An outstanding property of the SR-sheets is their high resistance to cellulose-degrading enzymes.

Sheets are acid washed for reduced calcium and magnesium contents. For distilled spirits filtration and ion sensitive products to avoid precipitation of calcium and magnesium sulfate after filtration.

SUPRApak SH Series Modules

- Undergo a proprietary treatment that results in extremely low levels of extractable ions (calcium, magnesium) making them the ideal solution for distilled spirits applications.

- Selectively reduce long chain fatty acid esters that are the main root cause for chill haze.

Consists of highly fibrillated pure cellulose (produced without the use of any inorganic material such as DE or Perlite). No ion release, this gentle filtration supports the production of premium quality beverages from coarse to microbiological reduction.

SUPRApak ZD Series Depth Filter Modules

- Made of pure cellulose filter sheet media and has been developed to meet the needs of the food and beverage industry for very pure depth filters without any DE (Diatomaceous Earth) or Perlite.

- Provide excellent filtration performance with full respect to product quality.

- Lowest impact on color and aroma during filtration of high-quality products.

Case Studies

To learn more about SUPRApak in action, download our case studies

Applications & Instructions for Use:

From minimizing waste in breweries to increasing filtration capacity and reducing process time in citrus oil de-waxing applications, you’ll find all you need in our application bulletins.

-

suprapak FBSUPRAPAKENb_FBSUPRAPAKENa

Download: