Most of the hydrogen today is produced from Natural Gas reforming. This process when combined with CO2 capture technologies is considerably less polluting and the Hydrogen produced is referred to as Blue Hydrogen. With electrolysis-based Hydrogen production (Green Hydrogen) yet to scale-up, Blue Hydrogen can provide the necessary large hydrogen volumes needed to de-carbonize many industries in the mid-term and help establish large-scale Hydrogen storage and transportation infrastructure to enable the future Hydrogen economy.

Why is filtration needed:

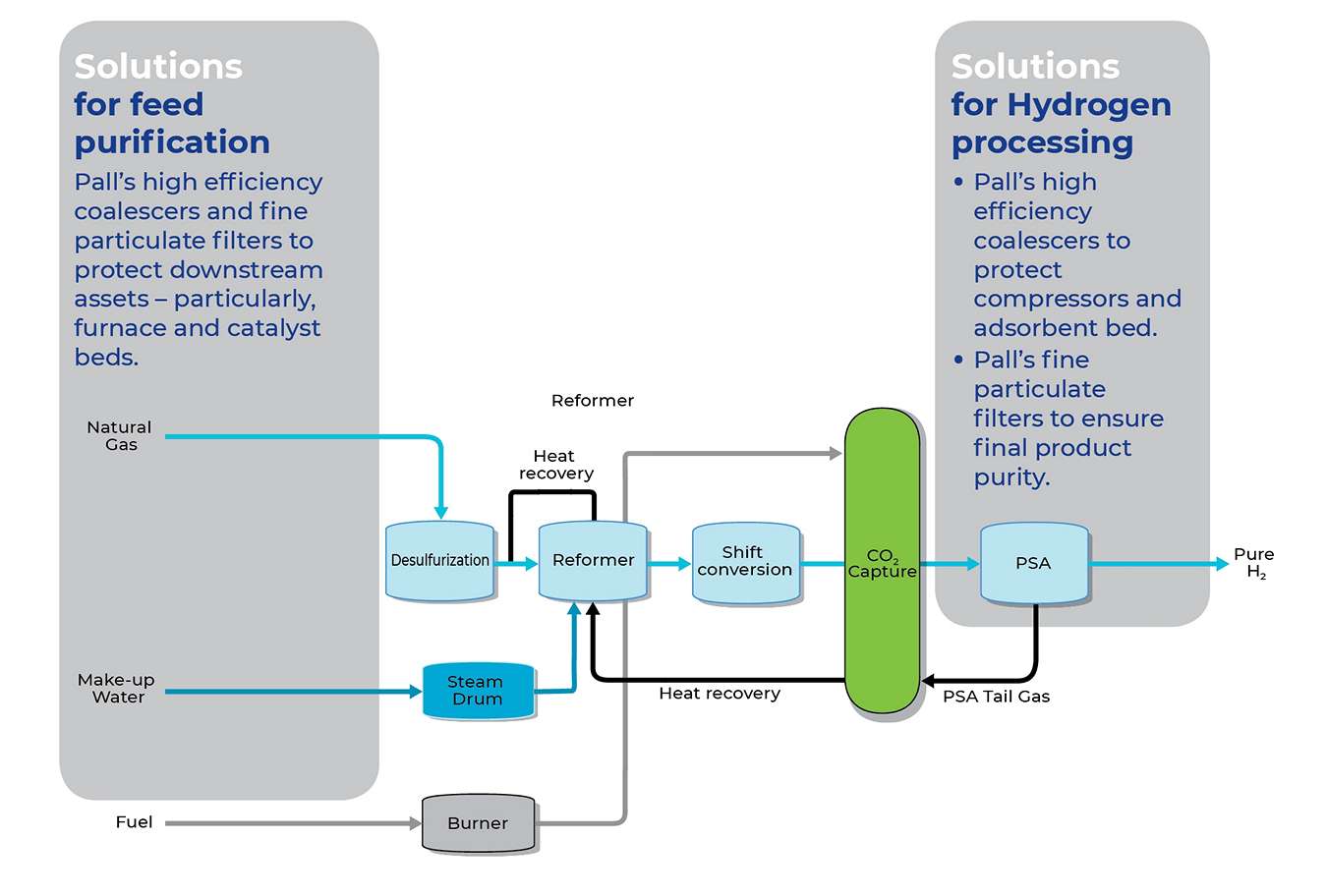

Filtration and separation solutions are highly important for Blue Hydrogen processes. Failure to remove liquid and particulate contaminants from feed streams and fluid re-circulation processes can result in inefficient operations and at worst, lengthy and costly downtime. Filtration applications include but are not limited to:

- Feed filtration to protect reformer and heat exchanger from corrosion particles

- Removal of liquids in the feed water which can lead to corrosion and catalyst deactivation

- Filtration of fuel gas feed to protect burners

- Protecting the adsorbent bed (PSA) from liquids and soot particles

- Removal of solid contaminants originating from process piping or drier beds to achieve high final product purity

How Pall can help:

Pall has filters and coalescers successfully installed in several Natural Gas reforming plants across the world, helping operators achieve the required feed, intermediate process and product quality. Together with Pall's advanced solutions in refining, carbon capture, biofuels and ammonia processes, Pall experts can help producers develop an overall filtration strategy that achieves the highest plant reliability and lowest filtration lifecycle cost. Pall's high efficiency solutions are particularly well suited for producers looking to develop modular, compact Blue Hydrogen production systems.

Typical Blue Hydrogen Process and Pall's solutions

To speak to one of our specialists, contact us.

Thank you!

You may also be interested in:

Carbon Capture and Storage