What is Cathode Active Materials?

Cathode Active Materials (CAMs) are crucial components in the cathode of a battery, particularly in lithium-ion batteries. These materials undergo electrochemical reactions that enable the storage and release of electrical energy. The choice of CAM significantly impacts the battery's performance, energy density, cycle life, and safety.

Challenges faced by CAM manufacturers

Manufacturers of CAM encounter numerous challenges due to the inclusion of various other chemicals in CAM, and the need to meet specific particle size distribution, preserve crystal structure, control surface area and porosity, and adhere to rigorous contaminant level specifications.

Watch our video to explore the transformative CAM process and understand how essential filtration enhances battery performance.

Pall Corporation: The Filtration Experts in CAM

Pall Corporation offers a wide range of purification and filtration products to optimize manufacturing processes. Our filtration solutions improve product purity, achieve the desired crystal size, and effectively eliminate contaminants. This helps producers meet cell assembly specifications and boost production yields.

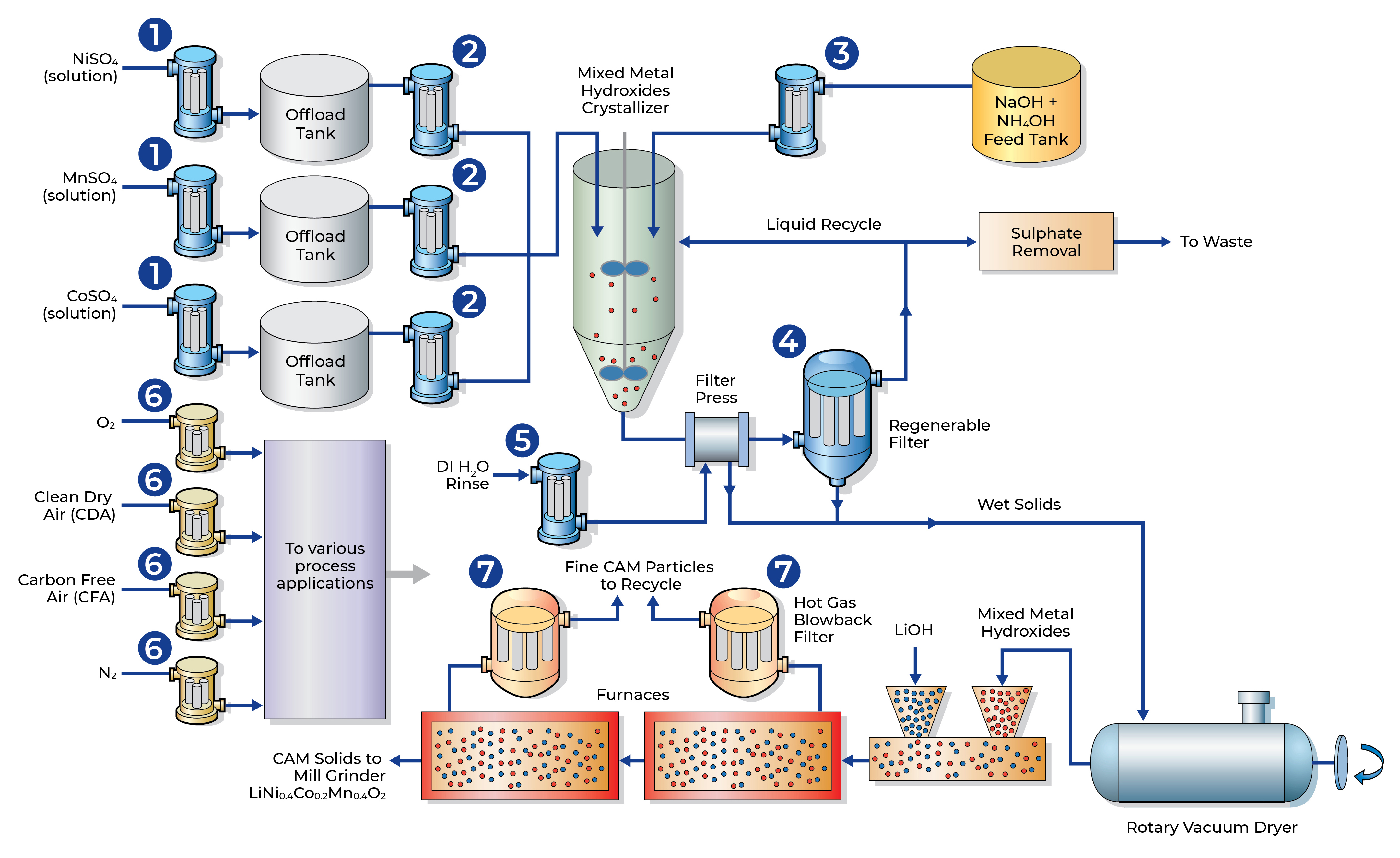

The process schematic for the CAM process below outlines the essential purification steps, beginning with raw materials, advancing through the precursor stage, and concluding with the final CAM product.

Typical Process Flow Sheet for Cathode Active Material Manufacturing

Filtration locations in the CAM manufacturing process

| No | Application | Filtration Value | Pall Product |

|---|---|---|---|

| 1 | Metal Sulfate Solutions to offload tank | Meet high purity specs for CAM Production | Meta Mesh Filter |

| 2 | Metal Sulfate Solution to Crystallizer | Meet high purity specs for CAM Production | 4.5 Micron Filter |

| 3 | NaOH + NH4OH | Remove undissolved salts, iron oxides and other solid contaminants | 0.5 Micron Filter |

| 4 | Mother Liquor and Water Wash | Recover mixed metal hydroxides | Regenerable Filter |

| 5 | DI Water | Reduce dissolved metals and solid fines in CAM slurry | 0.2 - 10 Micron Filters |

| 6 | Gas Filtration (O2, CDA, CFA, N2) | Remove fine particles from gasses | 0.3 Micron Filters |

| 7 | Hot Gas from Furnaces | Recover fine CAM particles | Hot Gas Blowback Filter |

Learn more about the solution that can support your applications or contact an expert today.

Enhance your process by speaking to one of our filtration experts in cathode active material production