Contact our team of filtration experts to discuss your plant-based protein process requirements

Plant Based

Crossflow filtration solutions designed to achieve high purity levels in plant proteins.

Due to changing consumer preferences towards plant-based diets, growing awareness of environmental sustainability, and advancements in plant-based protein technologies, the market is projected to experience significant growth by 2029, with estimates reaching between $20 billion and $46 billion. Plant-based diets are gaining popularity for their health benefits, sustainable production methods, and positive impacts on animal welfare and the climate. As a result, retail manufacturers and food service providers increasingly offer a diverse range of plant-based options.

The functionality of proteins—such as solubility, gelation, and emulsification—determines their application and usage levels. For instance, proteins for meat require good gelling and emulsification, while coffee creamers require high solubility and foaming capacity without gelling. Plant protein functionality varies by application and is influenced by the plant's breed, processing, and extraction methods. Proteins are classified into albumins, globulins, prolamins, and glutelins based on their 3D structure and solubility, with albumins being the most functional.

Plant Protein Challenges

The current method for extracting plant protein isolates often uses harsh chemicals like acids and alkalis, with pH levels from 4 to 11. These can denature proteins, reducing their quality and functionality. Typically, this process produces globulin-rich extracts while discarding valuable albumins, which are highly functional proteins. Losing albumins results in lower-value plant proteins.

Filtration Solutions for Producing High-Quality Plant Protein Isolates

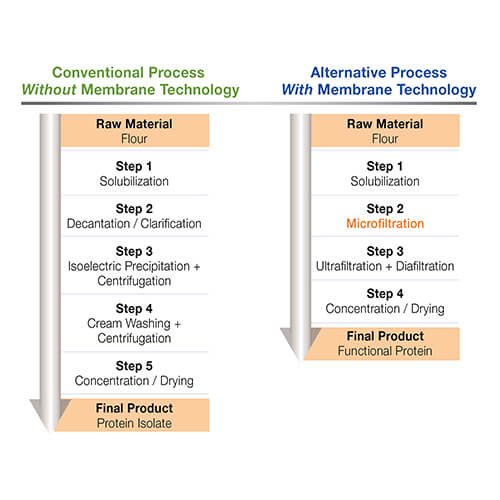

Membrane technology offers a unique value proposition as it maintains protein's natural functionalities and albumin retention with little to no need for chemical or thermal treatment. In other words, the isoelectric precipitation via chemical treatment could be eliminated, and clarification is achieved either via micro- or ultrafiltration (and sometimes both) using membranes. In addition, byproduct streams such as starch and fiber can be extracted in a separate market, making the overall production more sustainable. Pall's unique ceramic membranes have minimal effects on the protein structure, allowing producers to create superior quality and functional plant protein isolates that ensure higher profitability.

Pall's Membralox® crossflow filtration systems are fully enclosed and automated. This means they are regularly cleaned and sanitized in place with minimal labor requirements. They operate at suitable temperatures to prevent thermal denaturation of the product while maximizing separation performance. Their modular design allows any feed flow rate process, generally at constant throughput, possibly in full continuous mode (24/7), and into sequencing batch processes. Membranes' lifetime extends over years of continuous operation with consistent separation performances and capacity.

Membralox® Ceramic membranes advantages in the production of alternative proteins include:

- Better long-term ROI due to CAPEX

- Recovery/extraction and separation of the different types of proteins (albumins, globulins etc.)

- High protein purity without denaturation thus retaining functionality

- Lower OPEX is due to lower usage of energy, water and carbon footprint. Membrane separation optimizes drying process therefore less water and energy with shorter processing times.

Unlock the potential of your process with the perfect plant-based protein filtration! Reach out to one of our knowledgeable filtration experts today to discover the best solution tailored just for you.