Beer Filtration: A Brewers Guide

September, 2024

Why is beer filtration necessary?

With a wealth of new beers flooding the market for the beer enthusiast, ensuring your final product can compete by appealing in appearance and taste is crucial. To achieve this, efficient filtration of beer is necessary. Filtering beer is a process used to remove undesirable particles, such as yeast, sediment, and other impurities, to achieve clarity and stability in the final product. This process improves the beer's appearance, prolongs its shelf life, and enhances its flavor profile, making it more appealing to consumers.

In this blog, we discuss the importance of beer filtration, suitable methods, and the significant benefits of using Pall's filtration systems for beer production, instilling confidence in the quality of your brew.

What are the different types of beer filtration?

While many methods exist for achieving beer filtration, they vary in efficiency. Traditional filtration methods include cake filtration, which involves building a layer of solids on a filter medium; surface filtration, which separates particles at the surface of the filter medium; and cold filtering. However, these methods often produce a lot of waste and are not always environmentally friendly. They also provide varying results when it comes to filtration efficiency. However, membrane filtration systems support sustainability while improving process and cost efficiencies. Pall delivers a whole suite of membrane filtration solutions across the beer production process that offer the following benefits:

What are the characteristics of a well filtered beer?

Improved Clarity: A beer's aesthetics is vital in the final product. Cloudiness or haze can give the impression of a poorly crafted or contaminated product, with consumers often assuming that a clear beer is well-made. Specific beer styles have clarity standards. For example, lagers and lighter ales are usually expected to have excellent clarity.

The clarification process demonstrates the significant benefits of using membrane filtration systems instead of diatomaceous earth (DE) for brewers. DE is a substance derived from fossilized diatoms extracted from the earth, purified, finely milled, and then subjected to a heating process called calcination.

By using Pall filters, brewers can remove or reduce compounds that cause haziness in beer, making it look more visually appealing and last longer. These haze-causing compounds include yeast cells and mixtures of proteins, polyphenols, carbohydrates, or other particles suspended in the beer. Discover more about our clarification solutions here.

Enhanced Stability: Beer stability refers to its ability to maintain the desired flavor, aroma, and appearance over time. Filtering the beer helps to remove unwanted microorganisms like yeast and bacteria, which can cause off-flavors and spoilage during storage. This process extends the beer's shelf life and ensures consistency in its quality. Minimizing contamination and spoilage also reduces the risk of product recalls, which is essential for protecting a brand's reputation. Preserving a beer's flavor is crucial in brewing; any degradation can result in stale or off-flavors. It's necessary to protect against oxygen uptake during beer filtration, and membrane filtration is better for this purpose than cake filtration. Beer filtration is essential to remove yeast from fermentation and other components that could negatively impact the beer's flavor and appearance over time. Ultimately, beer filtration helps preserve the desired flavor, providing a clean and enjoyable taste.

Today's consumers expect a beer with a long shelf life. Colloidal stability - in addition to microbial stability, is crucial for the sufficient shelf life of packaged beer. Learn more about our beer stability solutions here.

What steps are necessary to achieve the best filtered beer?

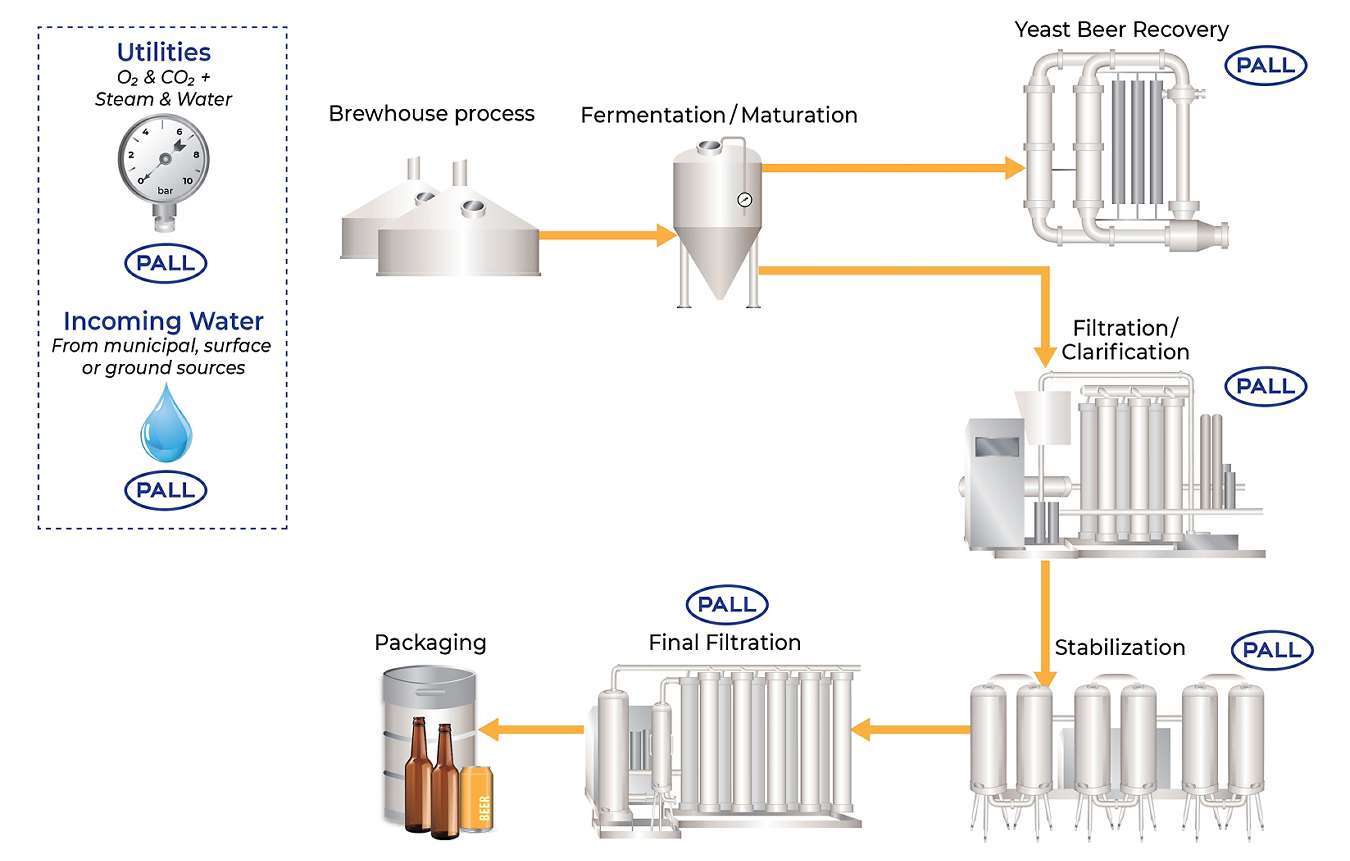

Beer Clarification: Clarifying beer involves removing solids and yeast after fermentation and maturation, and methods to achieve clarification sustainably have greatly improved.

Beer Stabilization: Colloidal stability and microbial stability are the main influencing quality criteria for a sufficient shelf life of packaged beer.

Final Filtration: This is essential in brewing to prevent harmful contaminants from reaching the final product and helps replace thermal pasteurization. More and more breweries apply beer final filtration, and with beer-specific membranes and solutions, this process can achieve maximum shelf life and satisfy consumer expectations.

Beer Recovery: Exploring how to increase extract yield while maintaining quality is essential to address the growing costs of raw materials and energy. Brewers can utilize Pall's beer recovery platform with membrane filtration to reclaim beer from excess yeast post-fermentation.

Pall's Solutions for Industrial Brewing

With a strong reputation for offering filtration solutions to various industries, we provide specialized filtration products and technologies tailored to the specific needs of breweries. Every Pall technology platform is engineered to reduce losses during production, ensuring that our processes meet the highest standards for maximum yield without sacrificing beer quality. Enhanced stability through filtration ensures that each batch of beer maintains consistent quality. By removing potential sources of variability and spoilage, Pall filtration systems help breweries deliver a reliable and consistent product to consumers, building trust and loyalty.

Unlocking the key to enhancing process efficiencies:

In the brewing industry, process efficiency is crucial, and Pall filtration systems play a significant role in improving beer production efficiency. Here's how filtration enhances process efficiency:

- High flow rates: Pall filtration systems provide high flow rates, allowing breweries to filter more significant beer volumes in less time. This helps increase production throughput, reducing the time required for filtration and improving overall process efficiency.

- Minimized downtime: Pall filters are known for their durability and reliability, engineered to withstand the demands of continuous operation, minimizing downtime due to filter replacement or maintenance. This ensures a smooth filtration process and optimizes production efficiency.

- Streamlined operations: Pall filtration systems integrate seamlessly into existing brewery operations, allowing for efficient and streamlined processes. The filters can be easily incorporated into the production line, minimizing the need for complex setup or adjustments. This simplification of operations helps save time and resources, contributing to overall process efficiency.

- Reduced product loss: Efficient filtration with Pall systems helps reduce product loss during production. This saves on raw materials and ensures that the final product meets the desired quality standards.

- Improved quality control: Pall filtration systems give breweries better control over the filtration process, allowing for precise adjustments and optimization. Enhancing quality control ensures consistent filtration performance, reduces the risk of deviations, and leads to higher overall process efficiency and a more reliable final product. Breweries can minimize product losses due to off-flavors, spoilage, or other quality issues by removing unwanted particles and impurities.

- Cost-effectiveness: By improving filtration efficiency, Pall systems help breweries optimize resource utilization, such as reducing product loss and utilities consumption plus making filter aids like DE unnecessary. This can lead to cost savings in raw materials, energy, and labor, making the brewing process more economically efficient.

Subscribe to our blog to stay up-to-date on the latest food and beverage insights and trends

- Category

- Author

- Sort By