Contact us below to speak to our filtration experts.

From Tap to Tank: Water Consumption in Brewing

Apr, 2025

Brewing is an energy-intensive process that can require large amounts of water. As a result, water consumption and wastewater disposal pose significant environmental challenges for breweries when they struggle with excessive water consumption. Data provided by Asahi claims that the world average water consumption per hl of beer produced is around 4.5 hl.

As environmental concerns grow and regulations tighten, effective brewery water consumption strategies are essential for sustainable brewing. From raw materials to packaging and getting the beer out to customers, each part of the process can create carbon emissions, pollute water, and generate waste. Reducing water used in beer production preserves this precious resource and can lead to significant cost savings and enhance a brewery’s reputation among eco-conscious consumers.

Why Breweries Need to Conserve Water

There is no doubt that water is indispensable in brewing, so by adopting eco-friendly practices, breweries can not only minimize their environmental footprint but also contribute positively to their communities and the planet. Beyond the environmental advantages of water conservation, brewers can enhance their brand image, leading to significant economic benefits. Our global survey of 3,500 beer drinkers indicates a significant rise in sustainable beer consumption, with more than eight out of ten beer drinkers currently trying to reduce their carbon or water footprints or expressing interest. Consumers are concerned about the environmental impact of their favorite beverage and expect breweries to adopt sustainable practices to earn their loyalty.

Brewery Water Consumption: The Regulatory Landscape

In addition to environmental concerns, breweries face increasing regulatory pressures to adopt sustainable practices. Government agencies and industry bodies are establishing strict guidelines to reduce water consumption and promote responsible water management. Breweries are encouraged to implement sustainable practices that align with broader sustainability goals now widely embraced in the industry. By prioritizing water conservation, a brewery can enhance its reputation as an environmentally responsible business, attracting eco-conscious consumers and partners.

Water Savings Equal Cost Savings

Efficient water management also leads to substantial cost savings. Implementing water-saving technologies and practices can significantly reduce operational costs. Lower water usage means decreased utility bills, less energy required for heating and treating water, and reduced costs associated with wastewater disposal. Investing in efficient water management systems can provide long-term financial benefits while ensuring that breweries remain competitive in a rapidly evolving industry.

Effective Water Conservation Techniques

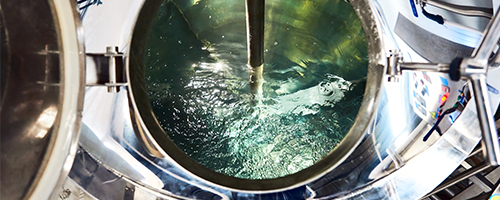

One critical approach is to utilize water-efficient brewing equipment. Many modern brewing technologies are specifically designed to optimize water usage without sacrificing product quality. Breweries can significantly reduce their water consumption by investing in equipment that features advanced filtration and water management systems. These systems can enhance the efficiency of water usage during various brewing processes and improve the quality of the water being utilized. For example, advanced filtration technologies can effectively remove impurities and contaminants, resulting in cleaner and better-tasting beverages while reducing the water needed for rinsing and cleaning equipment. One notable instance of this is DE-free filtration, which utilizes less water. In the early 2000s, Pall discontinued the production of DE (diatomaceous earth) or Kieselguhr filters. During a time when DE was the dominant technology in beer filtration, Pall shifted its focus to innovating crossflow membrane filtration for beer clarification. This technology was developed to eliminate DE from the beer production process. Membrane filtration removes the need for pre-and post-runs. This method significantly reduces water consumption when used with smaller vessel volumes—compared to DE filters that achieve the same beer throughput.

Effective water management strategies can recycle and reuse water throughout the brewing cycle, optimizing consumption rates and ensuring that every drop is used efficiently. This approach contributes to sustainability efforts and helps breweries lower operational costs related to water usage, making it a wise investment for both the environment and the business.

Monitoring and Measuring Water Usage

Effective water conservation in the brewing industry begins with a thorough understanding of water usage patterns, making water audits an essential practice. Regular water audits allow breweries to identify areas of excessive consumption, pinpoint inefficiencies, and implement targeted strategies for improvement. These audits provide invaluable insights that can significantly reduce water use, ultimately benefiting the environment and the bottom line.

With this in mind, Pall has implemented IoT-based digital information and process management for all our beer systems. By extending real-time data management through IoT, constant access to data is made available across the organization in user-defined-secure formats.

Breweries can leverage advanced technologies such as flow meters and data analytics platforms to facilitate accurate water consumption tracking. These tools enable real-time water usage monitoring at various stages of the brewing process, allowing for immediate adjustments and better-informed decision-making. By integrating these technologies into their operations, breweries can gain a comprehensive view of their water footprint and identify opportunities for optimization.

Once a brewery establishes a baseline through audits and monitoring, setting benchmarks and goals for water efficiency is crucial. These targets should be realistic, measurable, and aligned with the brewery’s sustainability objectives. By regularly reviewing progress against these benchmarks, breweries can foster a culture of continuous improvement, encouraging staff to engage in water-saving initiatives. Ultimately, a focused approach to monitoring and measuring water usage enhances operational efficiency and contributes to a more sustainable brewing industry.

Innovative Solutions for Sustainable Beer Brewing

Our forward-thinking engineers have developed systems that prioritize environmental sustainability. Utilizing our cutting-edge filtration solutions will enable breweries to reduce their environmental footprint by lowering water and energy consumption and minimizing beer loss. Contact us to see how we can support your sustainability efforts on the form provided, or for more information on our beer filtration solutions, visit here.

- Category

- Author

- Sort By