Blog

What is Chill Haze and How Do You Remove It?

December 2, 2020

Today’s consumers enjoy drinks that blend “innovation with premium products,” and because of that, cocktail culture and craft whisky continue to surge in popularity. According to Grandview Research, the overall global whisky market size expects a compound annual growth rate (CAGR) of 6.4% over the next five years. This growth is driven by the consumer’s increasing disposable income levels and changing preferences.

Whisky, in particular, is known for its distinct flavors and glossy, clear appearance. So what happens when a whisky pour appears cloudy in a glass?

What is Chill Haze?

Spirits such as whisky are very fragile and sensitive liquids. Water and alcohol levels in the spirit influence the solubility of turbidity-inducing substances. Once a whisky cools - for example, if ice is added to a glass of the product - some of the compounds, specifically the esters and the fatty acids, stick together. The small particles that are formed give the spirit a cloudy or hazy appearance. This is referred to as chill haze.

Despite the chill haze not impacting taste and flavor and remaining safe to drink, consumers still expect a visually clear drink. Anything less could be perceived as inferior or flawed, and it may deter someone from purchasing the product again. Therefore, removing chill haze is an important step for whisky producers to supply a consistent product and remain competitive.

What are the challenges with traditional chill haze removal?

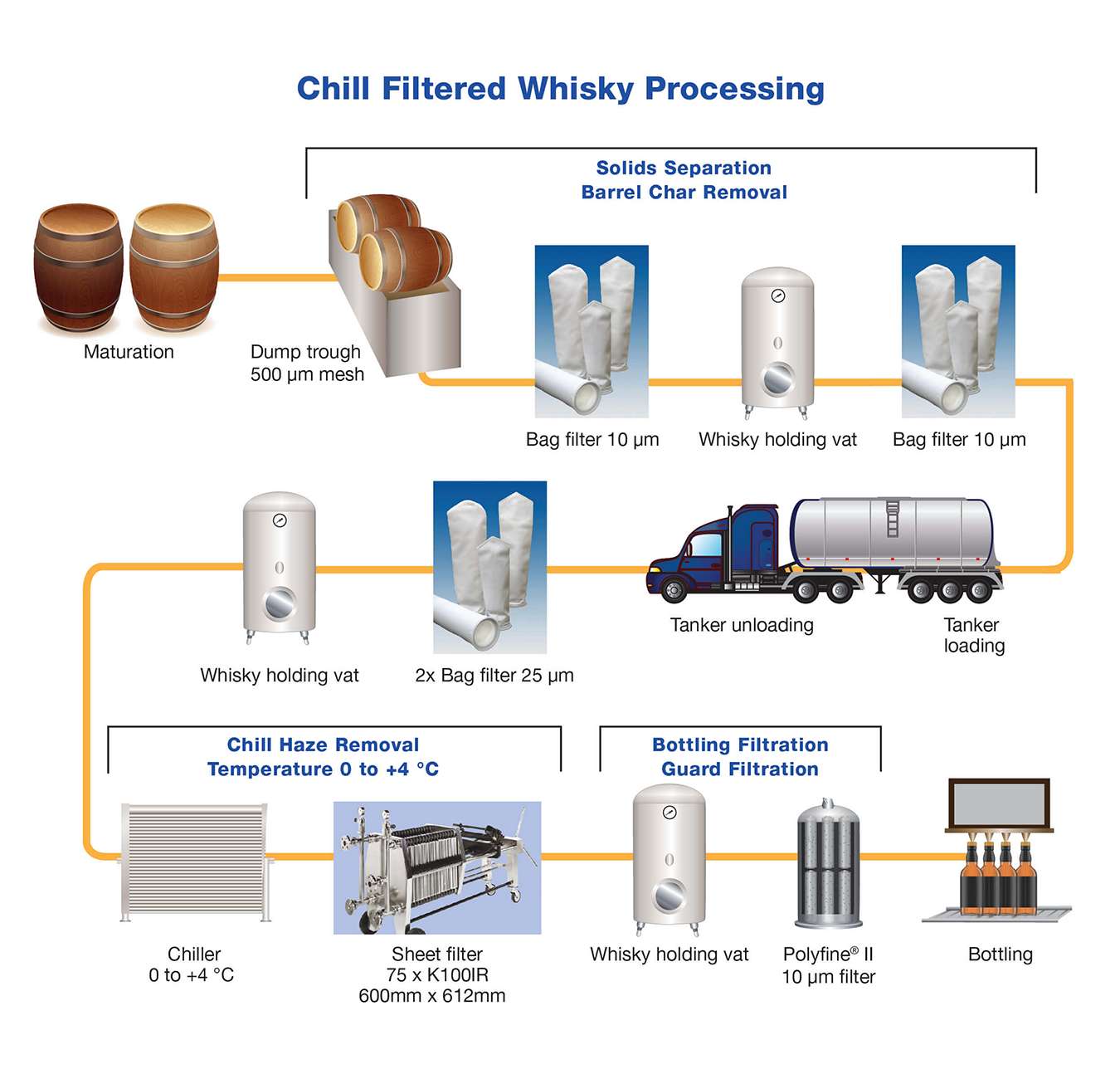

Whisky producers typically use a heat exchanger for chilling followed by filtration to remove chill haze. The purchase, maintenance, and running costs of the heat exchanger make it one of the most expensive parts of the process, depending on the required flow rate and size of the distillery.

Lowering the spirit temperatures to between -2 °C (28.4 °F) and +4 °C (39.2 °F) before bottling can create long-chain fatty esters, the cause of chill haze. In addition to causing chill haze, long-chain fatty esters can leave an unwanted taste, unlike short-chain fatty esters, which give whisky its taste and flavor.

Adsorbing long-chain fatty esters while keeping short-chain fatty esters is achievable by filtering through depth filter sheet-based media. However, it is inevitable that some of these important flavor compounds will also be removed. This is a problem because many whisky producers don’t want to compromise flavor to deliver a clear product.

Process Improvement: Whisky Distillery Case Study

Pall worked with a leading Scottish distillery to eliminate increased turbidity, which was out of specification for their processes. Monitoring downtime caused by turbidity revealed a 0.5% reduction in availability of the whisky production process. After analysis, the existing mechanical process was found to be one of the causes of the turbidity.

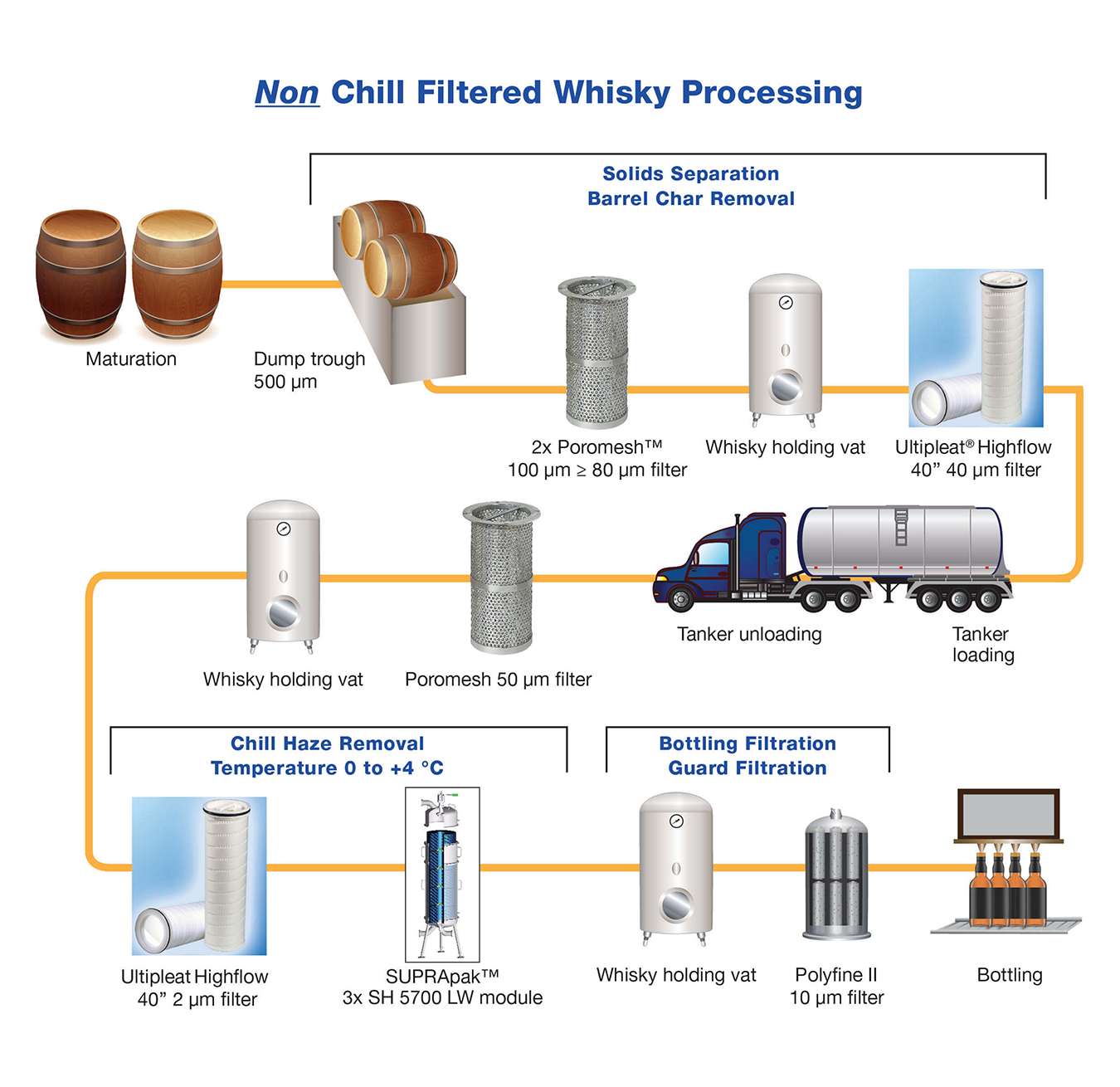

With support from Pall, the distiller decided to monitor the impact of un-chilled whisky through Pall’s SUPRApak™ L Series modules. Using an entirely new configuration of filter sheet material, the modules feature a unique design and flow configuration. Fluid travels through the sheet parallel to the sheet surface, resulting in far better filtration performance than flat sheet filtration, in which fluid travels perpendicular to the sheet surface. This innovative flow pattern called “edge flow” maximizes the adsorptive filtration capability of the sheet media, which enhances the removal of chill haze colloids and other haze-causing substances.

How is filtration at ambient temperatures with SUPRApak modules more effective?

The major mechanism that drives the removal of chill haze in distilled spirits using sheet media is adsorption. Unlike surface filtration, adsorption can retain contaminants through the thickness of the sheet media. Adsorption is highly influenced by the contact time of the haze colloids with the filter media. Classical sheets used for chill filtration have a thickness of 3.5 to 4.5 mm depending on the type used in the process. When the spirit is pumped through the filter sheets, it passes the given sheet thickness from the un-filtrate to filtrate side of the filter press and then exits the filter. With “edge flow” technology the distilled spirit has multiple passes through the depth filter sheets, comparable to the use of multiple flat sheet filter presses in a row. The use of SUPRApak SH modules in combination with a non-chill filtration process considerably improved the turbidity of the bottling vat whisky and allowed for elimination of the expensive chilling process. The distillery experienced an increased throughput and overall improvements in production. Additionally, they benefitted from reduced production costs throughout the entire process including no drip loss, improved availability of the filtration process, lower hold up volume and less risk of contamination with easier blow out procedure.

Conclusion: See through the haze

Achieving a cloud-free whisky for your consumers doesn’t need to be difficult. Analyzing your current process and making some changes can improve performance. For starters, leveraging the right technologies, such as SUPRA modules help improve quality and reduce cost. The result? A quality, crystal-clear product that you can be proud of. To find out more about our solutions for efficient chill haze removal, contact us.

Subscribe to our blog to stay up-to-date on the latest food and beverage insights and trends

- Category

- Author

- Sort By