What makes filtration critical for bio-feedstock processing?

There are a variety of waste feedstocks used in biorefineries, each of which varies in its composition and quality.

As a result:

- Contamination types vary considerably

- There is a wide range of contamination levels

- Variability of contamination size distribution

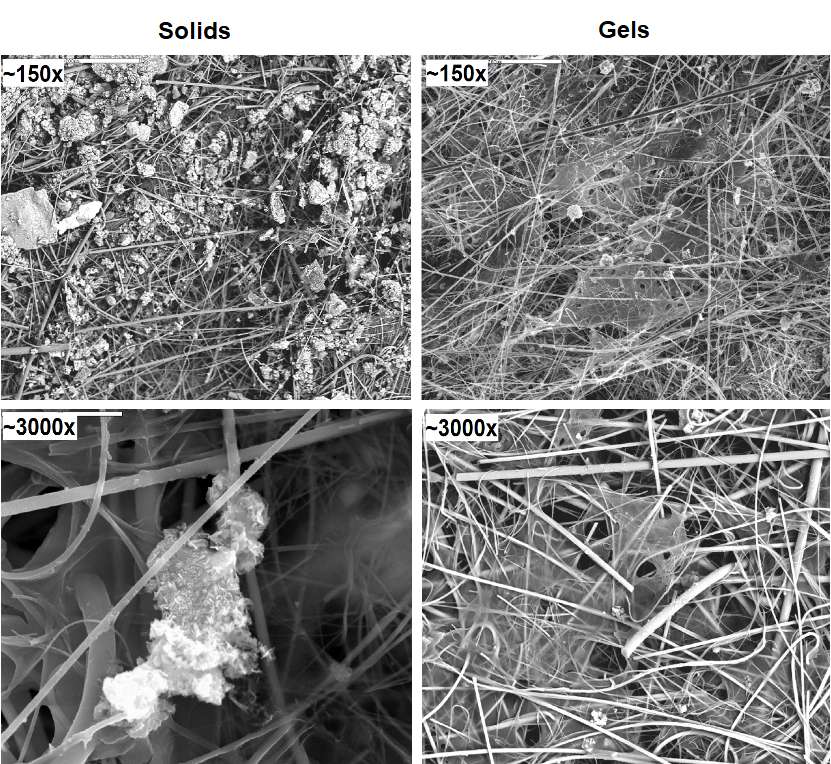

- Gel-like particulates are present

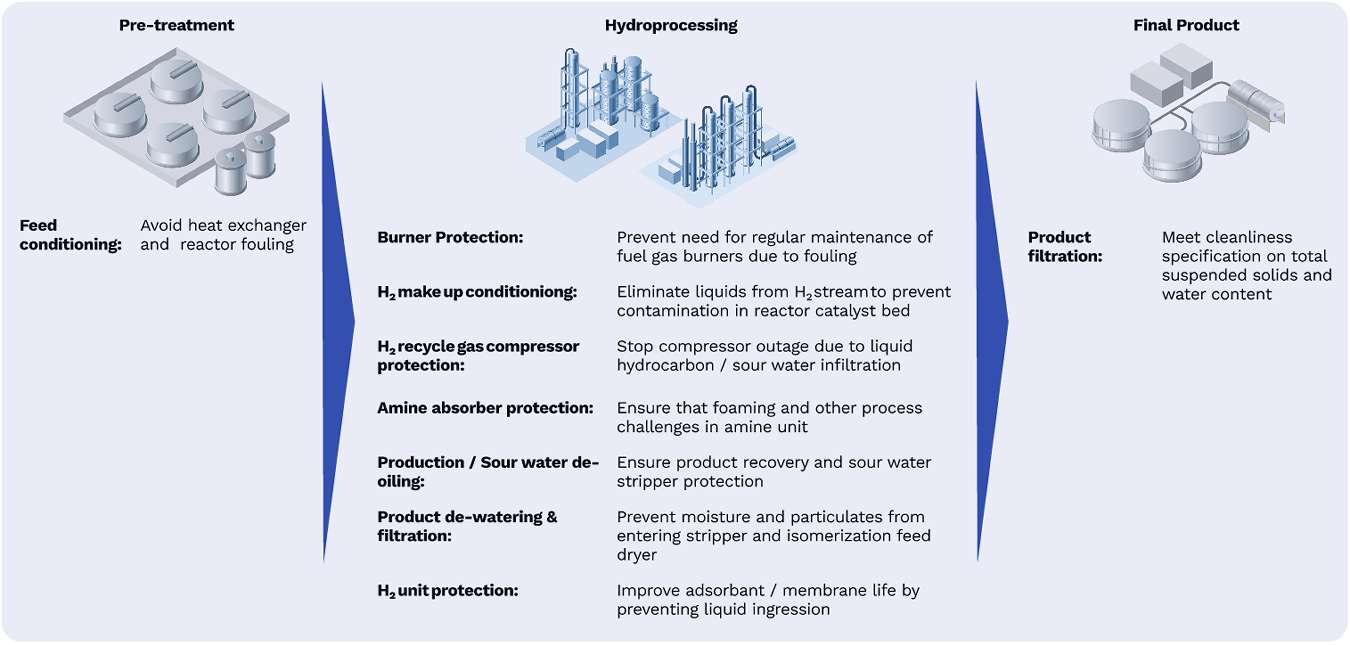

Despite pretreatment, bio-feedstock tends to degrade during transportation and storage. These particulate impurities and gels can cause severe damage to downstream equipment if left unfiltered.

In addition, bio-feedstocks typically contain an abundance of oxygen that gets converted to CO, CO2, and H2O during hydro processing. Depending on the type and proportion of biobased feedstock inserted into the refinery, the volume of gaseous products and moisture generated may differ significantly and impact refinery operations.

Some of the challenges include:

- Additional hydrogen demand

- Higher gas treatment and removal capacity needed

- Removal of additional co-produced water

Poor filtration and separation choices often have million-dollar consequences. The increased risk of moisture and contamination in catalysts and critical equipment due to bio-feedstock processing may lead to frequent downtime to repair/replace these expensive pieces of technology. Investing in an efficient, high-quality filtering system is essential to protect downstream equipment and to ensure installations run smoothly with less downtime.

Benefits of using high-performance filtration technology