Pall Cleanliness Cabinets

Component Cleanliness is the best insurance to avoid failures.

Assured Component Cleanliness Measurement

As fluid systems become more sophisticated and less tolerant to dirt, controlling and measuring cleanliness has become a vital part of the manufacturing process. Every manufactured part potentially carries “built-in” contamination to the system.

Pall Cleanliness Cabinets (PCC) are self-contained units providing accurate, reliable and repeatable procedures to extract particulate contamination from component surfaces for subsequent analysis.

The PCC enables operators to assess the cleanliness levels of manufactured parts and components in accordance to ISO 18413, ISO 16232 and VDA 19 procedures.

Contact our team of filtration experts for more information on improving the efficiency of the your processes.

Hitting the mark with cost and labor efficiency

Why Choose PCC?

Without standard, repeatable cleanliness validation, manufacturers and suppliers cannot meet industrial ISO cleanliness standards. PCC provides:

- More automated, repeatable process for checking parts cleanliness

- Rapid to blank value to start test sampling in much less time (up to 50% quicker)

- Less human errors involved

- Quicker to spot a quality issue ... less rework

The only cabinets to offer a fully integrated HEPA filtered laminar air flow clean room test environment

- You can trust the results ... no risk from environmental cross contamination

- Employees not exposed to harsh chemical or pressurized systems

Excellent, comfortable access to working area with no need for a protective barrier

- Reduced risk of operator contamination

- Ease of handling parts

Supplied in standard lab friendly or larger shopfloor sized units

- A cabinet to fit your available space and size of components

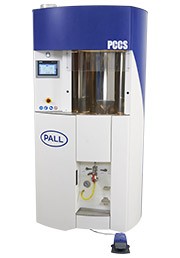

Choose PCCS:

PCCS is the ideal solution for small components (i.e. bearings, plastic hoses, injectors, gear box components, etc.).

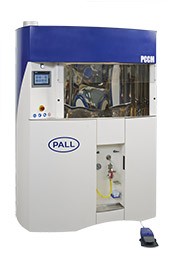

Choose the PCCM:

PCCM is the perfect choice for medium size components (i.e. small rods, crankshafts, camshafts, actuators, etc.).

Choose the PCCL:

PCCL is the preferred choice for larger sized components (i.e. engine blocks, steering gear, etc.).

All Pall Cleanliness Cabinet variants feature an easy to use, colour touch screen user interface.

See the full range of Component Cleanliness Cabinets here:

- PCCS -- Small sized Cleanliness Cabinet

- PCCM -- Medium sized Cleanliness Cabinet

- PCCL -- Large sized Cleanliness Cabinet

- PCC-FR -- Flushing Rig

- PCC-41KC -- Medium sized PCC - Asia supply only

Component Cleanliness Management (CCM)

Pall’s Component Cleanliness Management (CCM) program provides products and services for accurate, reliable, and repeatable component and fluid cleanliness measurement.

The CCM program includes the supply of cleanliness cabinets, cleanliness evaluations, specification development, and customized training, all undertaken in cooperation with our customers to optimize in-plant processes.

For more information about Pall’s Component Cleanliness Management program, please contact us.

Our Products

Leading the Industry with product solutions that fit your customers needs.

How can we help?

If you are looking for innovative filtration solutions, you’ve come to the right place. Our knowledgeable subject matter experts are here for you. Contact us for more information. Thank you and we look forward to assisting you shortly.