Ensuring Purity in Green Hydrogen: Pall's Method for Quantitative Determination of Liquid Aerosols in Hydrogen Gas Streams

October, 2024

As the global energy transition accelerates, green hydrogen production is poised to play a pivotal role in achieving a sustainable future. By 2030, many hydrogen projects currently in the demonstration phase (<100MW) are expected to scale up to large-scale production (>500MW). With this growth comes increased engineering complexities and a heightened need for efficiency and reliability. A critical aspect of this is maintaining the purity of hydrogen, as contaminants introduced during production, compression, storage, and transportation can significantly impact performance and safety.

The Importance of Hydrogen Purity

Hydrogen purity is crucial for various applications, particularly in hydrogen liquefaction units and fuel cells. Contaminants—whether solid, liquid, or gaseous—must be meticulously removed to meet stringent specifications. Ensuring hydrogen purity not only enhances the efficiency of the end-use applications but also contributes to the longevity and reliability of the infrastructure involved.

Pall's Approach to Contaminant Detection

At Pall, we have developed a robust method for quantitatively determining free liquid aerosol concentration in hydrogen gas streams under process conditions. Our method allows for the detection of aerosols down to single-digit ppm levels, facilitating comprehensive contamination monitoring at any stage of the hydrogen production process. From compressors and other process equipment to distribution pipelines and storage, our technique ensures that contaminants are identified and addressed promptly.

The Methodology

Our approach involves isokinetic sampling of the gas and the collection of contaminants on specialized membrane-based collectors. The quantitative determination of these retained components is achieved through gravimetry. This principle can be applied to determine the concentration of both aqueous and hydrocarbon aerosols. The sampling test unit includes an isokinetic probe, collector membrane, and associated instrumentation, all tested under process conditions.

Field Testing and Results

Field tests were initially conducted with natural gas and more recently within the environment of green hydrogen production. The results demonstrated that our method could quickly and accurately detect liquid contaminants in both natural gas and hydrogen gas. For natural gas, identifying contaminants led to a better understanding of flow meter fouling at gas distribution stations and the implementation of effective separators to clean the gas.

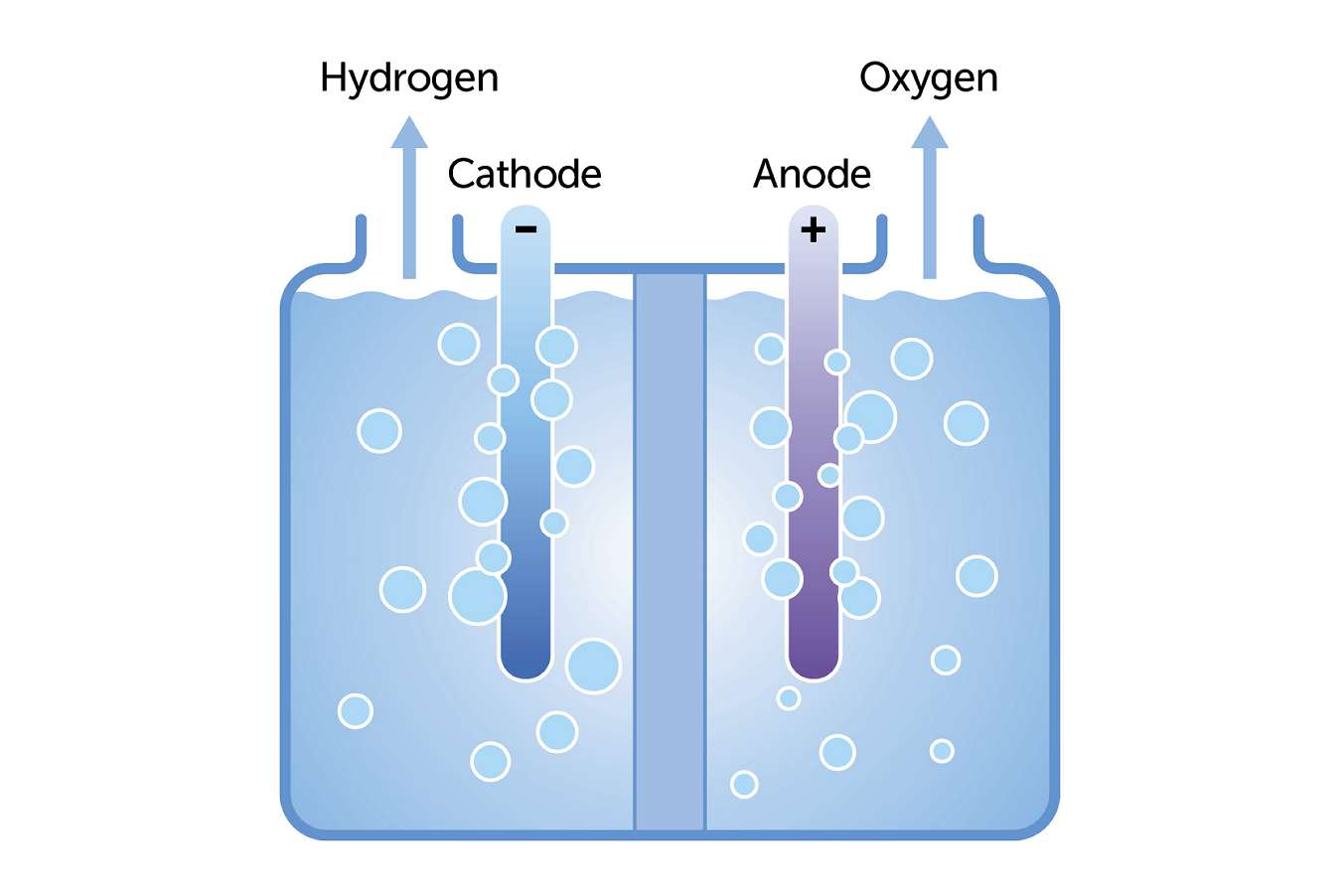

In the context of green hydrogen, our method provided valuable insights into the efficiency of gas treatment technologies and the quality of hydrogen gas, particularly concerning water-based aerosol carryover from electrolyzer cells into the gas stream.

Benefits for the Hydrogen Industry

Our method offers the hydrogen industry a unique and efficient way to monitor contamination throughout the hydrogen value chain—from production to end-use. This capability is instrumental in developing and evaluating appropriate technologies for each step of hydrogen production and distribution. By ensuring that hydrogen remains free of contaminants, we can significantly enhance the performance and reliability of hydrogen-based applications, paving the way for a cleaner and more sustainable energy future.

Conclusion

As we continue to advance the production of green hydrogen, maintaining hydrogen purity will be paramount. Pall's innovative method for detecting and quantifying liquid aerosols in hydrogen gas streams provides a critical tool for ensuring this purity. By facilitating quick and efficient contamination monitoring, we are helping the hydrogen industry to develop robust and reliable processes that will support the global energy transition.

Stay tuned for more insights and developments in hydrogen purification and other cutting-edge technologies from Pall. Together, we can drive the energy transition forward and achieve a sustainable future. For more information on our green hydrogen filtration solutions visit our dedicated webpage

Subscribe to our blog to stay up-to-date on the latest insights and trends

- Category

- Author

- Sort By