VRFII Varnish Remediation System

Application

A power generation company based in British Colombia, Canada, operating an Alstom GT24B 250MW gas turbine on a combined cycle, experienced stiction of the servo-valves when modulated for various control functions during turbine start-up and shut-down.

The turbine lubrication system of 30,000 litres capacity using Chevron GST® ISO 46 lube oil had been in service for approx. 7 years, protected by 7 µm absolute rated return-line filtration. Fluid monitoring procedures highlighted a high level of oil degradation by-products in the fluid presenting itself as ‘varnish’ within the fluid system, for example the inside of the main flow filter housing indicated the presence of a heavy brownish coating of varnish material.

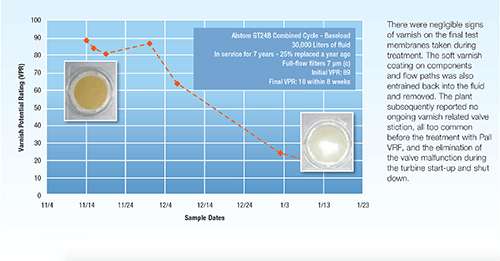

The Varnish Potential Rating or VPR℠ (i.e. the potential likelihood of a lubricant's tendency to form varnish deposits,) was measured via membrane patch colorimetry method and found to be at a level of 89, indicating a high‐level of insoluble oil degradation products associated with varnish, beyond the operators ‘critical’ limit. Immediate treatment was required to return the lube oil to normal recommended operating conditions. This required a robust filter solution for varnish removal in power plant.

Solution

A Pall VRF varnish remediation unit was deployed in a kidney loop configuration for varnish removal in power plant. The skid uses a cooler to maintain optimum oil temperature for the most efficient varnish removal before passing the oil through a 3-module filter housing, rated at 11 GPM flow rate. The filter is made with a specially designed adsorptive media, optimized for removal of varnish-forming precursors from the oil. At the outlet the oil flows through a Pall SRT technology, antistatic filter, rated at ß12(C) ≥ 1000 for additional protection and improved fluid cleanliness, before returning to the main reservoir.

Result

An improvement in VPR℠ was seen, falling from 89 to 18 (below the normal recommended limit of 36) following multiple passes of the system fluid through the VRF unit over a period of 8 weeks. There were negligible signs of varnish on the final test membranes taken during treatment. The soft varnish coating on components and flow paths was also entrained back into the fluid and removed. The plant subsequently reported no ongoing varnish related valve stiction, all too common before the treatment with Pall VRF, and the elimination of the valve malfunction during the turbine start-up and shut down.

There were negligible signs of varnish on the final test membranes taken during treatment. The soft varnish coating on components and flow paths was also entrained back into the fluid and removed. The plant subsequently reported no ongoing varnish-related valve stiction, all too common before the treatment with Pall VRF, and the elimination of the valve malfunction during the turbine start-up and shut down.

For more information on removing the threat of varnish from your turbine lube system, contact us at Pall by filling out the form in the right-hand sidebar.

Contact our team of filtration experts for more information on improving the efficiency of your processes.