Discover the right spirits filtration process for your needs! Contact us to speak to an expert.

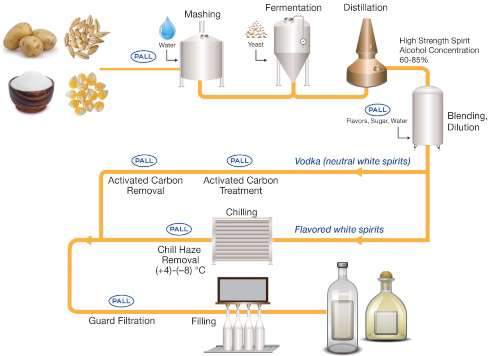

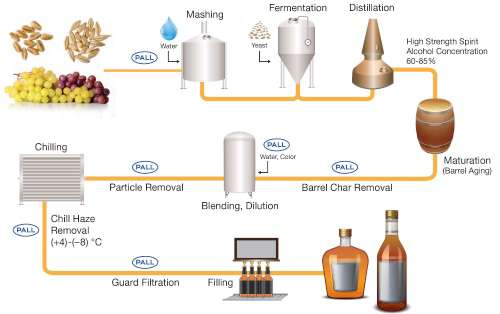

Whether you need chill haze removal in whisky, activated carbon treatment in vodka, or final filtering in blending water, Pall has the technology and expertise to help you reduce costs, improve output, and maintain complete process control.

White & Brown Spirits Process Flow Diagram

Depth Filtration

Pall’s unique depth filter technologies, developed specifically to meet the challenging requirements of distilled spirits filtration, can bring sustainable value to your production process.

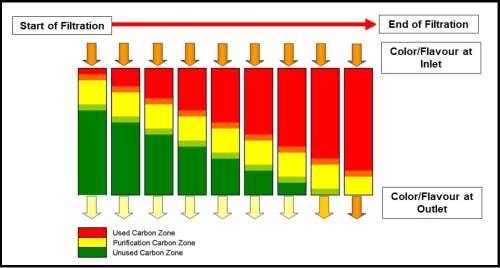

Activated Carbon

Powdered activated carbon (PAC) is used widely in the food and beverage industry for adsorption applications. The use of bulk PAC has significant drawbacks relating to handling bulk carbon powder, cleaning of the process equipment and time and costs associated with carbon removal. The new Seitz® AKS FB immobilized carbon filter media addresses these concerns by incorporating activated carbon within a matrix of cellulosic fibers. This immobilized carbon media can be coupled with a downstream protective filter paper to prevent carbon particle shedding downstream of the filter.

Pall Filtration Solutions for High-Quality Spirits

-

Chill haze Removal

-

Activated Carbon Treatment

-

Particle Filtration

Meeting customer expectations for clear spirits and prevent chill haze formation after bottling can be accomplished by removal using filtration. Pall’s experience in spirits filtration is unmatched – discover more about our solutions for chill haze filtration of whisky and other brown and white spirits.

Seitz AKS FB Series depth filter sheets were developed to satisfy the general-purpose carbon adsorption applications in the distilled spirits industry. For the removal of off odor and/or to adjust the color of distilled spirits, Pall's technology and expertise can help you reduce costs, improve yield, and maintain complete process control. With unique depth filter technology and innovative high flow filter configurations developed specifically to meet the challenging requirements of spirits filtration, Pall can bring sustainable value to your production process.

For better product quality and higher chemical stability after processing, explore the new Seitz® AKS FB

For distilled spirits like whisky, tequila, vodka, rum, gin and brandy, consumers expect a visually clear, bright product. To meet this requirement, producers need to deliver a bottled product free of suspended particles and haze.

Particle removal in spirits occurs at different stages in the production process including:

- Barrel Char Removal

- Activated Carbon Removal

- Guard Filtration

- General Particle Removal

SPIRITS Products

For more information about our range of products, explore our product catalog.