What is Chill Haze?

Distilled spirits contain a diverse array of substances that originate from their raw materials and from the barrels used for ageing. These substances include fusel oils, fatty acids and their esters.

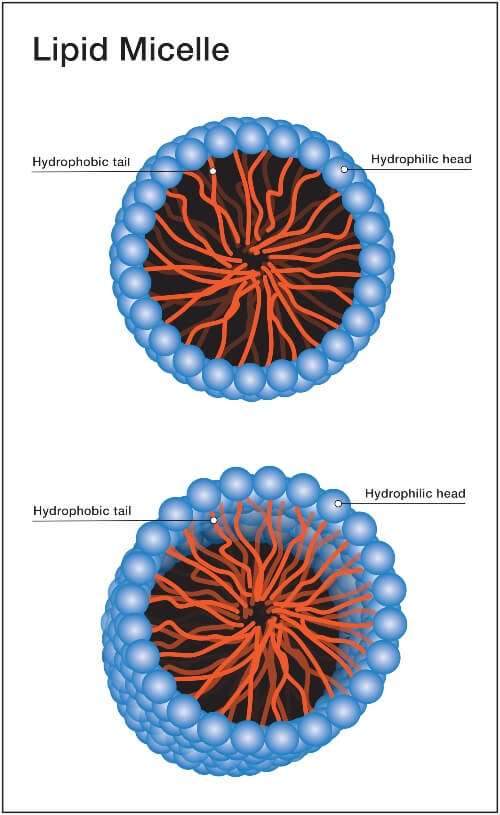

When water is added, these compounds, which are insoluble in water, form micelles and result in turbidity also known as chill haze. While this haze may form in white spirits, it is more common in brown spirits like whisky.

Impact of Temperature and Aging on Chill Haze Formation

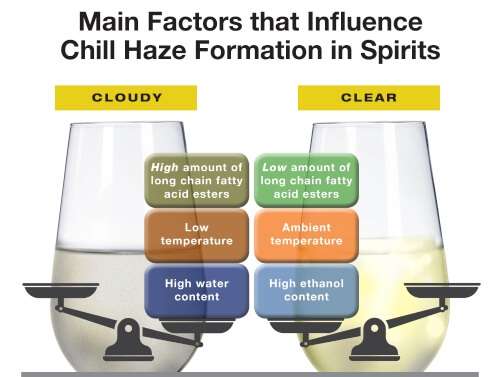

Chill haze formation typically increases at lower temperatures, in lower proof products given the presence of more water, and in products with longer ageing time in wood. Decreasing temperature fosters precipitation, agglomeration of particles, and hardening of oils and waxes.

Balancing Flavor and Clarity in Spirit Filtration

While certain compounds like fatty acid esters cause chill haze, they also have an important positive effect on the sensory characteristics of the spirits.

Therefore, it is important to selectively remove the longer chain acid esters which are associated with unwanted flavors while maintaining the short chain fatty acid esters that are associated with the desirable aroma components.

How to Remove Chill Haze

To meet customer expectation for clear spirits and prevent chill haze formation after bottling, the majority of brown spirits undergo a process that involves chilling the spirit to temperatures below 0 °C (32 °F). This forces the chill haze to form which can then be removed by filtration.

While mechanical particle removal plays a role in the filtration process, adsorption is the major mechanism in chill haze removal, making filter sheet-based technologies an ideal solution.

With Pall’s traditional flat filter sheets and new unique modular formats, Pall’s experience in spirits filtration is unmatched. Learn more about our products for chill haze filtration of whisky and other brown and white spirits.

Niro Filter Press

-

Seitz K Series Filter Sheet

Download: -

Seitz® IR Series Depth Filter Sheets

Download: -

SUPRApak™ Depth Filter Modules

Download:

To Chill or Not to Chill?

For many of the world’s spirits, chill haze has historically been removed by cooling and filtering as previously described. In recent years, however, there is increasing industry interest to experiment with new filtration methods that eliminate the chilling process altogether.

“Non-Chill Filtered” whisky is now being produced by several leading brands, representing a significant shift in a very traditional industry.

The decision to filter at ambient or after chilling at lower temperatures can be influenced by several factors. The main driver for filtration at ambient temperature is quality. Recent studies have demonstrated improved quality by avoiding the refrigeration step. Additionally, availability of refrigeration, which can be very expensive, can also be a major consideration for a new craft producer.

SUPRApak™ Housing

Pall Products for Spirit Chill Haze Removal