Effective Automotive Parts Washing Solutions

Cleanliness is a critical element for reliability and service life in the automotive industry. Performance and dependability of finished goods is often reliant on the cleanliness of its components. Assembly of automotive powertrain systems can often include hundreds of different components which could be directly in a forced air or fluid path, causing downstream contamination, which will ultimately effect long term performance.

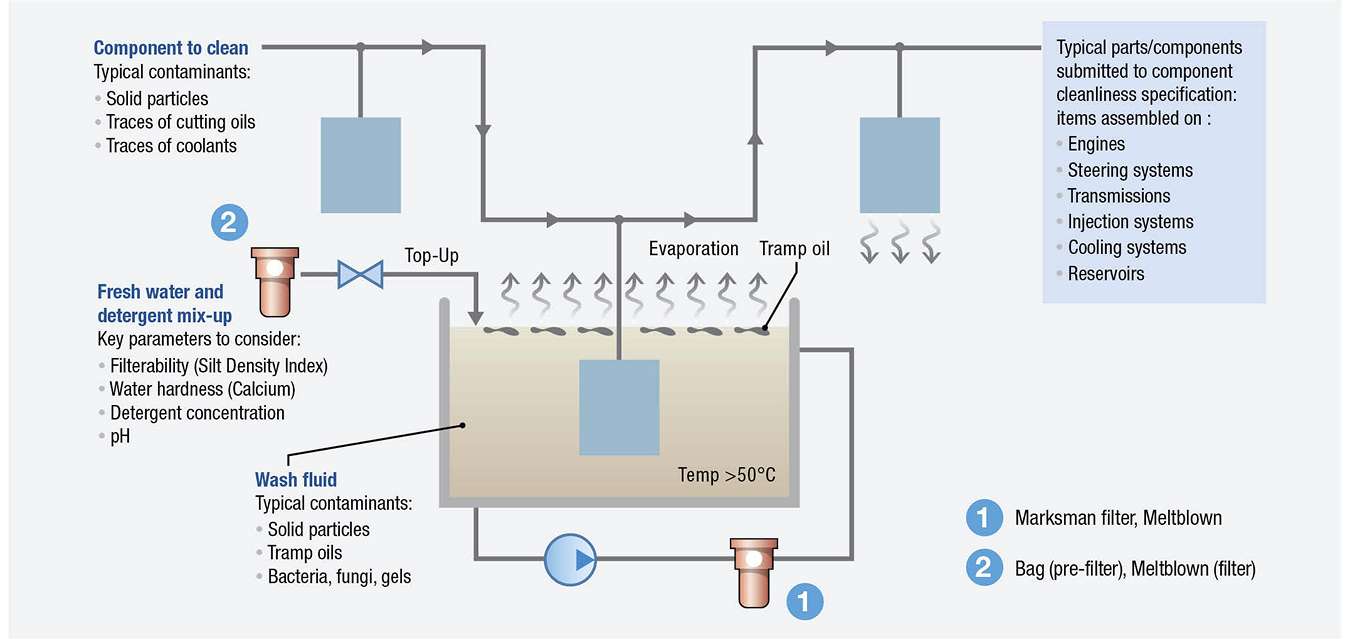

Critical to avoiding contamination is the parts washing process. Not only does it help machinery to operate at the maximum level of efficiency, it will also prevent additional issues happening further down the line caused by contaminants. Almost all the parts in contact with a system fluid onboard a vehicle are now subject to a component cleanliness specification. This includes parts/components that are assembled on engines, steering systems, transmissions injection systems, cooling systems and reservoirs.

Solutions

Tackling these issues can be done effectively with our automotive parts washing solutions. For the industrial water circuit, Melt Blown Media achieves optimal particulate removal through varying fiber diameters.

Marksman™ Series Filters are a customizable and cost-effective filtration solution for automotive wash fluid systems. These superior filters surpass traditional bag filter performance in both filtration efficiency and consistency. A wide range of filtration media, such as polypropylene, nylon, and glass, allows for a fit-for-purpose filter system.

Other benefits include:

- Delivers the filtration performance of 10 bag filters, resulting in fewer filter changeouts

- User-friendly changeout process further reducing the length of scheduled maintenance downtime.

- Inside to outside flow path ensures contaminants are trapped on the filter, eliminating the risk of contaminating fluid downstream during filter changeout

In-plant applications include automotive parts washing, machine tool coolant, make-up water, pre-and post-RO, E-coat filtration, paint and coatings, water and oil-based metal working fluids, wash rinses and baths. Pall filters can be installed into existing hardware to upgrade filtration. For example, upgrading nominally rated bag filters to Pall filter cartridges improves fluid cleanliness and can increase service life and lower maintenance costs

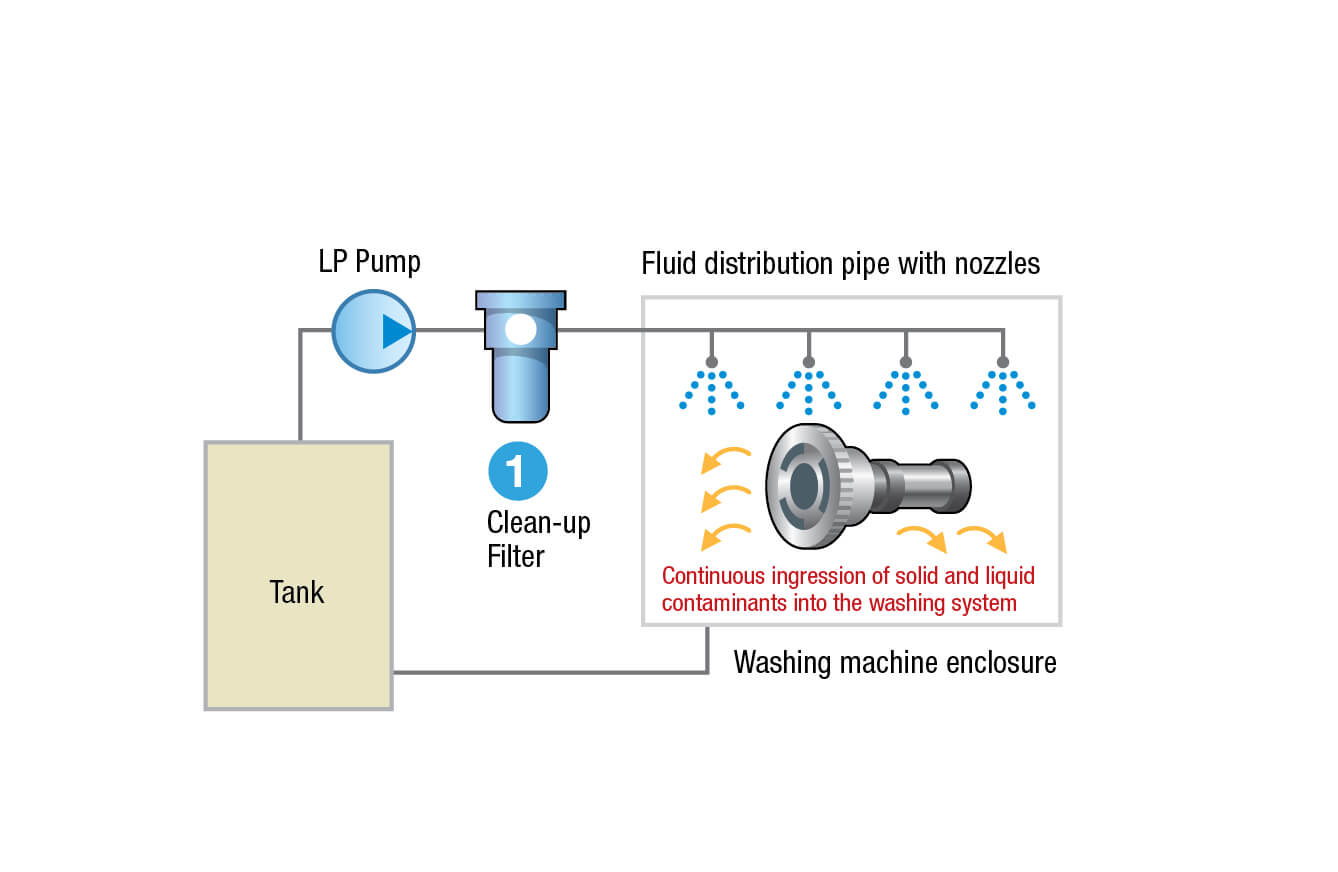

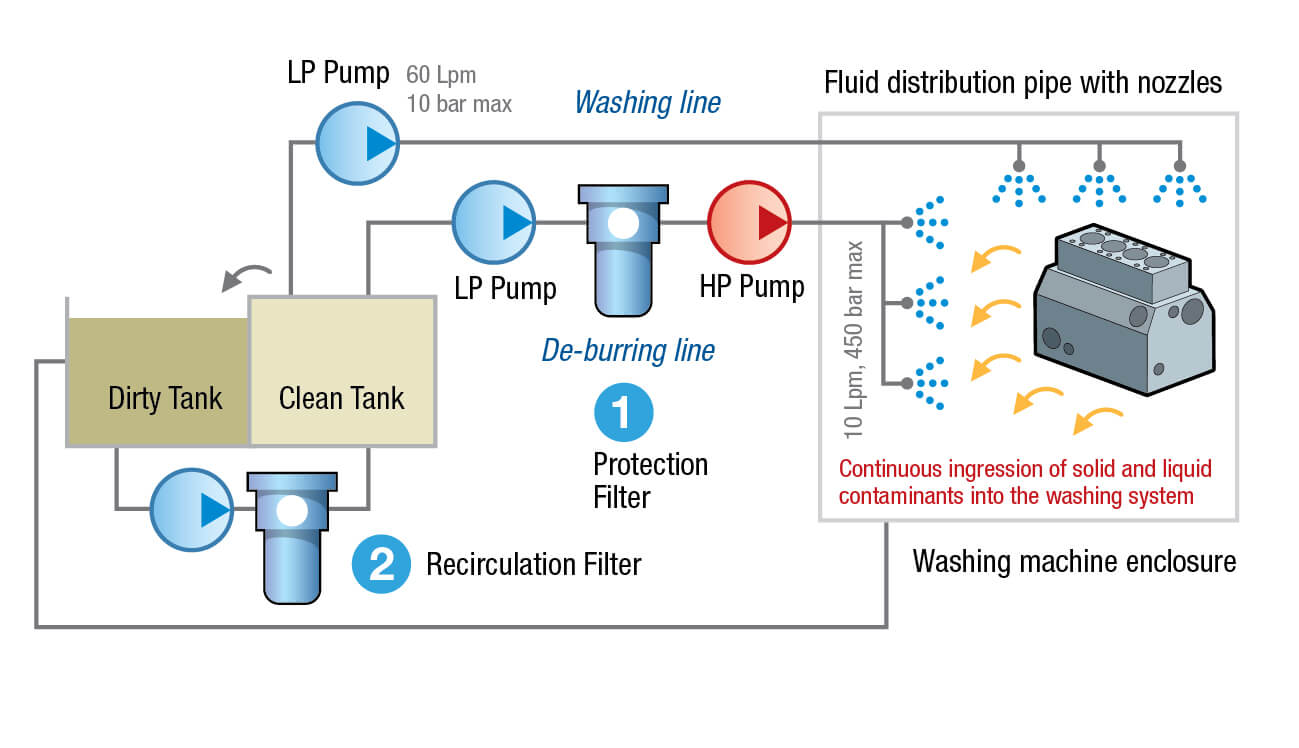

Spray – Low Pressure Washing Machines

Effective filter solutions for tramp oil include:

The following is also suitable for different applications:

- Critical application: Marksman XLD filter

Additionally, Pall Clarisep Crossflow Filtration systems remove tramp oil, suspended solids and bacteria from water-based fluids to maintain fluid condition for extended service life. For more information, please contact one of our specialists on the form provided.

Pall Filtration technology applied on automotive parts-washing process and systems enables the car maker/Tier supplier to:

- Reach and maintain the required wash fluid cleanliness level throughout the filter service life

- Reduce reject rates due to solid contamination issues

- Generate cost savings due to less wash fluid drainage and change-out and higher uptime of the wash system

For more information on improving the efficiency of your processes, contact our team of filtration experts.

-

Marksman™ XLD Series Filter Elements

Download: -

Marksman™ NXA

Download: -

PCM500 Low Viscosity

Download:

Our Products

Leading the Industry with product solutions that fit your customers needs.

Oil Recovery Treatment

Fluid Line Cleanliness