The unsolvable solved

Safeguarding health, protecting critical assets and improving product quality while minimizing emissions and waste are what we pride ourselves on.

We are passionate about helping you meet your most difficult challenges and have put together a range of solution stories from across industries. Discover the challenges and solutions that relate to you below.

Wineries Recover Higher Value Wine and Juice From Lees

Recovery of wine and juice from lees is a challenging yet unavoidable task for wineries globally. Decreasing wine surplus, stringent environmental and food safety requirements and increasing competition in the market challenge wineries to filter lees more efficiently and economically. Discover how a winery in Australia achieved this with solutions from Pall.

Solving Foaming in Amine Regenerator

For this Middle-Eastern gas production company producing sales gas and natural gas liquids (NGL), severe foaming issues had started to affect the gas throughput, causing amine carryover and production delays. Discover how they removed the entrained liquids in the feed gas, reducing the foaming in the amine generator.

Removing Water from Diesel and Eliminating Off-Spec Product Incidents

At a major Canadian oil company operating a 138,00 bbl/day refinery, removing water from diesel downstream was a critical challenge that needed addressing. Through the implementation of AquaSep® coalescer technology, off-spec product incidents decreased significantly, thereby saving on reprocessing and transportation costs.

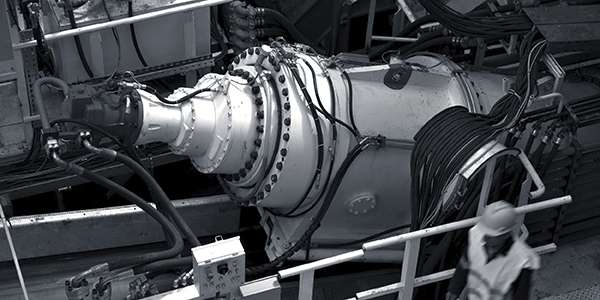

27,000-Megawatt Loss Turns into Mega Savings

Premature plugging, filter bypass, end-cap failures and system trips due to high filter differential pressure were the challenges experienced by a United States combined-cycle plant. Discover how our experts helped them to tackle these issues and eliminate contamination during start-ups.

Power company improves its start-up and shut-down procedures by removing varnish from the control system.

Discover how a power generation company in British Columbia resolved valve stiction issues during turbine start-up and shutdown, resulting in final tests that indicated no varnish or further stiction problems or valve malfunctions.

How Tier Suppliers Reduced Operating Costs by 22%

The global internal combustion engine (ICE) market is expected to reach 370 million units by 2030. But driven by environmental legislative requirements, powertrain OEMs and tier suppliers must continuously improve their designs without increasing costs. Discover how a major tier supplier achieved it in this case study.

Paper Mill Successfully Reduces Operating Costs by 40%

As a competitive sector, the paper industry is constantly looking for innovative solutions and process efficiency improvements. Learn how a major paper mill in Europe reduced its running costs while improving efficiencies across the entire process.

Pall Rental Purifier keeps tunneling project on track

Tunneling machines are sophisticated, expensive pieces of equipment, often running 24/7 in the harshest operating conditions. Water ingression in the gearbox and lubrication systems is a common problem that can lead to significant maintenance costs and unscheduled downtime. Read on to learn how Pall Oil Purifiers were able to prevent equipment failure and save one operator $125K a day in downtime costs

Naphtha Feed Purification has Major Impact on Steam Cracker performance

One critical application in the ethylene production process is feed stock purification. Contaminated gas or liquid feed stocks can lead to high cost furnace repairs and increased environmental emissions. Read our case study on how Pall PhaseSep coalescers ensured Naptha gas feedstocks were free of liquid and solid contaminants, protecting the Steam Cracker in an ethylene production plant.

Still have a question? No problem.

Submit your question with your contact details in the form below and one of our team will be back to you quickly.