Contact a brewery specialist below.

Beer Filtration Solutions for Breweries

Discover the full potential of your brewing process with our innovative beer filtration systems

Why Filtration Matters in Beer Production

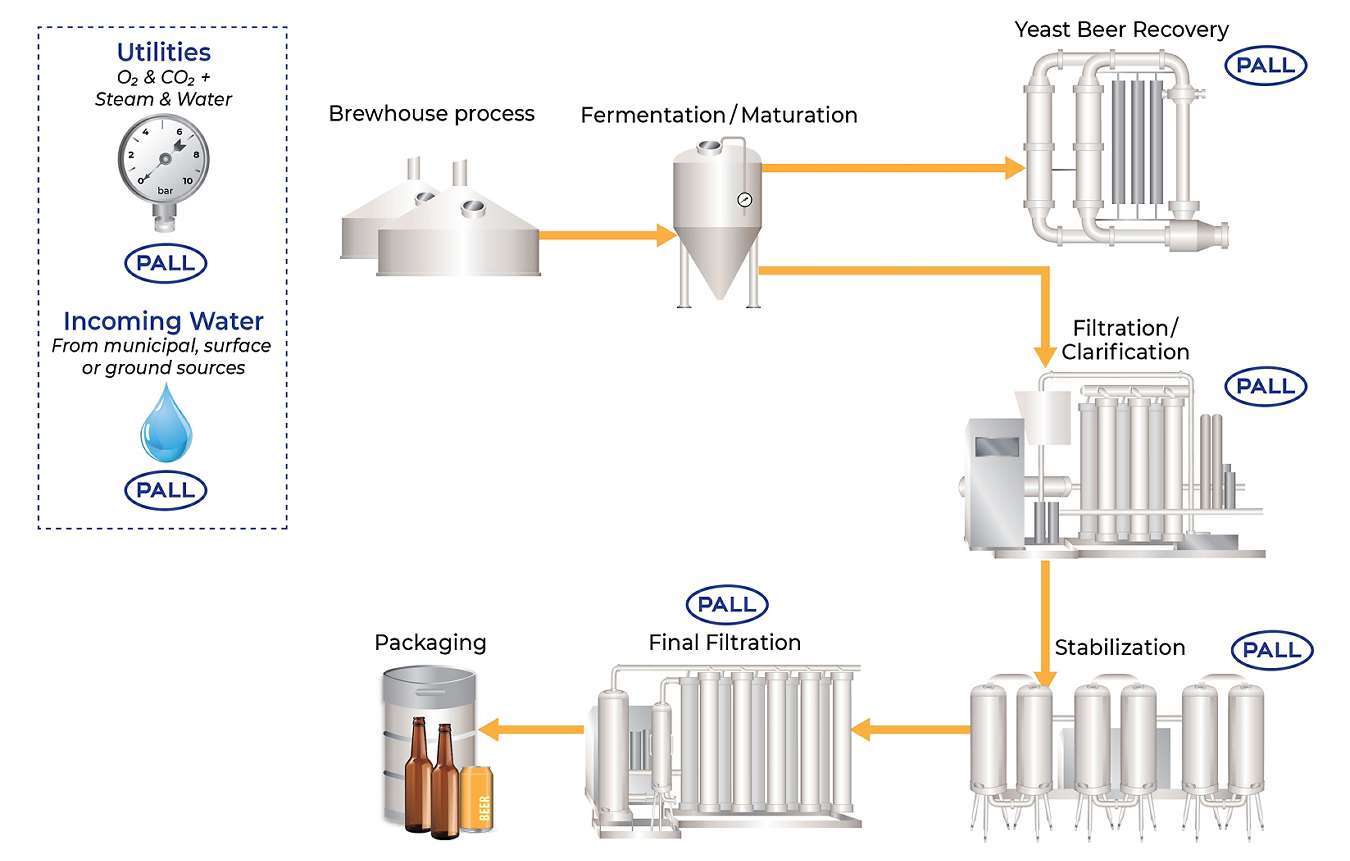

The industrial brewing process must meet high standards to preserve the brew's unique taste, flavor, purity, and freshness. Consistency is essential for achieving a distinct flavor profile, which relies on raw water quality, microbial stabilization, sterile air, removal of yeast and bacteria, clarification, stabilization and final filtration.

Microbial spoilage poses a considerable challenge in the brewing industry, where unwanted contaminants such as particles, colloids, bacteria, and wild yeast can dramatically alter both the flavor profile and safety of the final product. Brewers face the complex task of maintaining high quality standards while striving for cost efficiency and adherence to sustainability goals. This delicate balance requires innovative solutions to ensure that the brewing process remains effective and sustainable.

Investing in commercial beer filtration solutions is crucial for breweries aiming to achieve significant cost savings while advancing their sustainability objectives without compromising the quality of their products. By refining filtration processes at every stage of brewing, breweries can effectively tackle contamination, minimize waste, enhance water efficiency, and elevate product quality. These optimizations lead to reduced operational expenses and lower maintenance requirements, while ensuring that every brew continues to meet the highest expectations.

Filtering beer with Pall's technology addresses breweries' needs for maximum yield, minimizes production losses, and preserves beer quality. Discover why commercial beer filtration matters and our effective solutions for every stage in the brewing process below.

Learn more about our beer IoT systems